Firefighters perform rescues every day in many different situations. This incident shows while rescues like this may not happen every day, when they do, rope rescue skills are invaluable.

5/16/2022 – Lafayette, Louisiana Rope Rescue

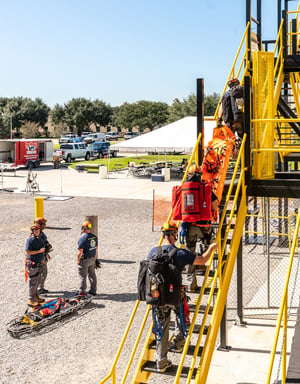

Combining strength, skill, knowledge, and quick thinking, rope rescue is a dangerous task firefighters face. The art of rappelling and the selection of appropriate knots and anchors to ensure the safety of rescuers and their patients are skills that are vital to emergency responders.

Two construction workers were left hanging from their safety harnesses after the scaffolding holding the workers failed at Ochsner Lafayette General Medical Center. According to the Lafayette Fire Department, one person received major injuries, and another received minor injuries.

Two construction workers were left hanging from their safety harnesses after the scaffolding holding the workers failed at Ochsner Lafayette General Medical Center. According to the Lafayette Fire Department, one person received major injuries, and another received minor injuries.

Firefighters from the St. George Fire Department in Baton Rouge were covering Station 5 in Lafayette so their brother and sister firefighters could take the time to honor their fallen brother. Fortunately, the St. George Firefighters that were there happened to be trained in rope rescue – exactly what was needed to rescue the stranded workers.

Captain Neyland and Lieutenant Gateley brought them safely down to the ground where Captain Brown and Lieutenant Gonzales were ready to render patient care. While rescues like this may not happen every day, when they do, rope rescue skills are invaluable.

Photos courtesy of Lafayette Fire Department

Additional Resources

- Roco’s Quick Drills focus on tasks like patient packaging, tripod use, building anchors and setting up safe and efficient systems.

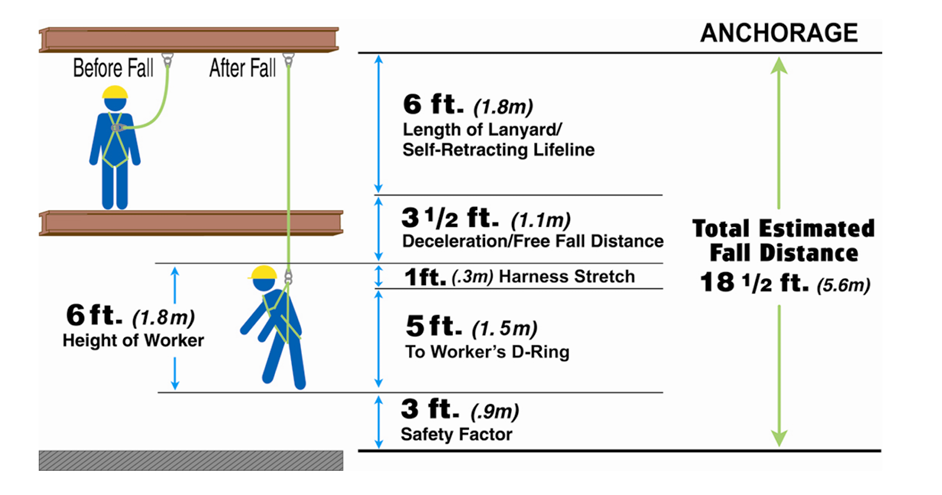

- 5 Tips for Working Safely at Heights - We’ve created a list of Top 5 safety tips to consider before starting work.

A quick look at NFPA 2500 reveals that the end user has significant leeway to determine rope and equipment size and strength. For example, Chapter 30 Selection (NFPA 1858)

A quick look at NFPA 2500 reveals that the end user has significant leeway to determine rope and equipment size and strength. For example, Chapter 30 Selection (NFPA 1858)

Roco provides Entergy with many highly trained and skilled confined space rescue teams across Arkansas, Mississippi, and Louisiana. Additionally, Roco’s Safety Services Division now provides Entergy with highly trained and motivated Certified Occupational Safety Specialists to add another level of depth to safety on large-scale outages and turnarounds. Our Safety Specialists have been involved in overall outage planning, safety consulting and observations throughout the outage, and overall support for anything that Entergy needed during their large projects. This year, Roco had the pleasure of providing oversite for two outages, including one major outage in Mississippi.

Roco provides Entergy with many highly trained and skilled confined space rescue teams across Arkansas, Mississippi, and Louisiana. Additionally, Roco’s Safety Services Division now provides Entergy with highly trained and motivated Certified Occupational Safety Specialists to add another level of depth to safety on large-scale outages and turnarounds. Our Safety Specialists have been involved in overall outage planning, safety consulting and observations throughout the outage, and overall support for anything that Entergy needed during their large projects. This year, Roco had the pleasure of providing oversite for two outages, including one major outage in Mississippi.