Manufactured exclusively for Roco Rescue by Skedco.

Sleek, portable and mission-driven – the new Roco Lowrider™ Compact Rescue Tripod is made for low, tight spaces. Originally designed by Roco tactical instructors to meet the mission-critical requirements of elite DoD special operations teams, the Roco Lowrider™ Rescue Tripod brings cutting-edge technology and hard-earned lessons to the civilian rescue industry.

Sleek, portable and mission-driven – the new Roco Lowrider™ Compact Rescue Tripod is made for low, tight spaces. Originally designed by Roco tactical instructors to meet the mission-critical requirements of elite DoD special operations teams, the Roco Lowrider™ Rescue Tripod brings cutting-edge technology and hard-earned lessons to the civilian rescue industry.

With a minimum height of 38-inches and a maximum working height of 60.5-inches, the Roco Lowrider™ can be used to extract patients from low overhead spaces using minimal personnel. Designed to be man-packable,

the Lowrider™ weighs only 32 lbs. and features header, anchors and legs connected with stainless steel bolts for maximum strength and weather resistance. The proven Skedco head design allows up to three separate

connection points for multiple rigging options. The anchors are well-balanced to handle rescue loads and each is anodized red for easy identification.

With its light weight, compact size and breaking strength of more than 20,000 lbs., your team’s working efficiency will be dramatically increased – all while staying LOW.

Key Features:

Key Features:

• Weight of 32 lbs., less than half the weight of a traditional tripod.

• Minimum height of 38-inches with a maximum working height of 60.5-inches.

• Minimum breaking strength of more than 20,000 lbs. at full extension.

• Anchors are anodized red for easy identification.

• No traditional tripod chain – 8mm cordelette provides hobbling capability.

Place Your Order Today!

-

Roco Lowrider™ Compact Rescue Tripod Kit

(Includes: compact tripod, 30-ft. 8mm accessory cord, one William Triact carabiner and carrying bag.)

While basic first aid and CPR may be the minimum required for rescue personnel

While basic first aid and CPR may be the minimum required for rescue personnel

Your company has a strong safety culture with outstanding employee participation. Everyone is committed to safety and goes out of their way to do things in the safest way possible. As a safety professional, everything is great in your world until suddenly, a “near-miss” report lands on your desk. Supervisors, managers, and company executives are now concerned, worried, or even stressed out about the fact that something unsafe just happened at their company! Many would-be quick to speculate that a near miss is a bad thing; however, as a safety professional, you know that this is not necessarily the case. The reality is, a near-miss or “good catch” report can be one of the most valuable tools for improving your company’s safety program.

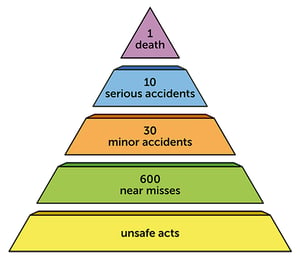

Your company has a strong safety culture with outstanding employee participation. Everyone is committed to safety and goes out of their way to do things in the safest way possible. As a safety professional, everything is great in your world until suddenly, a “near-miss” report lands on your desk. Supervisors, managers, and company executives are now concerned, worried, or even stressed out about the fact that something unsafe just happened at their company! Many would-be quick to speculate that a near miss is a bad thing; however, as a safety professional, you know that this is not necessarily the case. The reality is, a near-miss or “good catch” report can be one of the most valuable tools for improving your company’s safety program. In 1931, Herbert Heinrich published Industrial Accident Prevention: A Scientific Approach where he proposed a concept that would eventually become known as “Heinrich’s Law.” Heinrich’s law states that for every accident that causes a major injury, there are 29 accidents that cause minor injuries and 300 accidents that cause no injury (i.e., near misses).

In 1931, Herbert Heinrich published Industrial Accident Prevention: A Scientific Approach where he proposed a concept that would eventually become known as “Heinrich’s Law.” Heinrich’s law states that for every accident that causes a major injury, there are 29 accidents that cause minor injuries and 300 accidents that cause no injury (i.e., near misses). By performing a root cause analysis, you may learn that it was raining on the day of the near-miss and that the roof in your warehouse has developed a leak, causing a puddle of water to form, creating the unsafe condition that led to the incident. Simply instructing the employee to be more aware of the surroundings may prevent them from slipping again; however, it will not prevent the unsafe condition from reoccurring. The true root cause needs to be addressed; the roof must be repaired.

By performing a root cause analysis, you may learn that it was raining on the day of the near-miss and that the roof in your warehouse has developed a leak, causing a puddle of water to form, creating the unsafe condition that led to the incident. Simply instructing the employee to be more aware of the surroundings may prevent them from slipping again; however, it will not prevent the unsafe condition from reoccurring. The true root cause needs to be addressed; the roof must be repaired. Consider implementing google forms, phone applications, or even a universal near-miss email address. The key is to make the process to submit a near-miss as easy, quick, and painless as possible. For example, many companies now create QR codes that can be scanned, taking personnel right to the form to complete and submit. This can all be done for free with readily available resources around the internet.

Consider implementing google forms, phone applications, or even a universal near-miss email address. The key is to make the process to submit a near-miss as easy, quick, and painless as possible. For example, many companies now create QR codes that can be scanned, taking personnel right to the form to complete and submit. This can all be done for free with readily available resources around the internet. Chris McGlynn is a dynamic safety leader who serves as the Director of Safety at Roco Rescue and is dedicated to amplifying the company's safety success. As a Certified Safety Professional, Confined Space and Rope Rescue Technician, and Paramedic, Chris leverages his expertise to provide employees with the necessary tools, training, and support to work safely and efficiently. He also oversees Roco Safety Services, offering high-caliber safety professionals for special projects and turnarounds. As the VPP Coordinator, Chris ensures that Roco maintains its status as an OSHA VPP Star Worksite, continuing the company’s unwavering commitment to excellence in safety and health. Roco has been an OSHA VPP Star Worksite since 2013.

Chris McGlynn is a dynamic safety leader who serves as the Director of Safety at Roco Rescue and is dedicated to amplifying the company's safety success. As a Certified Safety Professional, Confined Space and Rope Rescue Technician, and Paramedic, Chris leverages his expertise to provide employees with the necessary tools, training, and support to work safely and efficiently. He also oversees Roco Safety Services, offering high-caliber safety professionals for special projects and turnarounds. As the VPP Coordinator, Chris ensures that Roco maintains its status as an OSHA VPP Star Worksite, continuing the company’s unwavering commitment to excellence in safety and health. Roco has been an OSHA VPP Star Worksite since 2013.