Manufactured exclusively for Roco Rescue by Skedco.

Sleek, portable and mission-driven – the new Roco Lowrider™ Compact Rescue Tripod is made for low, tight spaces. Originally designed by Roco tactical instructors to meet the mission-critical requirements of elite DoD special operations teams, the Roco Lowrider™ Rescue Tripod brings cutting-edge technology and hard-earned lessons to the civilian rescue industry.

Sleek, portable and mission-driven – the new Roco Lowrider™ Compact Rescue Tripod is made for low, tight spaces. Originally designed by Roco tactical instructors to meet the mission-critical requirements of elite DoD special operations teams, the Roco Lowrider™ Rescue Tripod brings cutting-edge technology and hard-earned lessons to the civilian rescue industry.

With a minimum height of 38-inches and a maximum working height of 60.5-inches, the Roco Lowrider™ can be used to extract patients from low overhead spaces using minimal personnel. Designed to be man-packable,

the Lowrider™ weighs only 32 lbs. and features header, anchors and legs connected with stainless steel bolts for maximum strength and weather resistance. The proven Skedco head design allows up to three separate

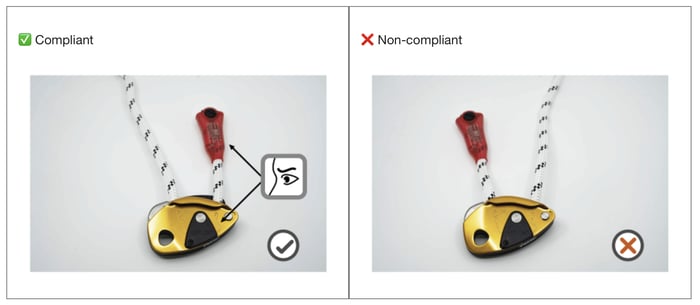

connection points for multiple rigging options. The anchors are well-balanced to handle rescue loads and each is anodized red for easy identification.

With its light weight, compact size and breaking strength of more than 20,000 lbs., your team’s working efficiency will be dramatically increased – all while staying LOW.

Key Features:

Key Features:

• Weight of 32 lbs., less than half the weight of a traditional tripod.

• Minimum height of 38-inches with a maximum working height of 60.5-inches.

• Minimum breaking strength of more than 20,000 lbs. at full extension.

• Anchors are anodized red for easy identification.

• No traditional tripod chain – 8mm cordelette provides hobbling capability.

Place Your Order Today!

-

Roco Lowrider™ Compact Rescue Tripod Kit

(Includes: compact tripod, 30-ft. 8mm accessory cord, one William Triact carabiner and carrying bag.)