We were so excited to see all the applicants for our Fire Department Scholarship Program – we decided to pick 10 instead of 1! The following individuals were selected to attend a Roco Urban/Industrial Rescue Essentials™ Course at no charge at the Roco Training Center in Baton Rouge.

Winners:

|

We will be getting in touch with the above individual winners to share the good news and what the next step is.

Roco Rescue hopes that this free training will help broaden the range of skills in confined space and rope rescue for firefighters and their departments.

Roco Rescue hopes that this free training will help broaden the range of skills in confined space and rope rescue for firefighters and their departments.

Click button below if you are interested in applying for the next Fire Department Scholarship Program selection.

Offer valid for USA-based emergency responders only based on space availability. Must be 18 years or older and physically fit to participate in hands-on rescue exercises. Offer is valid for limited time and subject to change without notice.

Machine entrapment rescues are another all too common situation in which responders need to isolate the area at the point of contact with the patient to prevent further movement. RESCUERS BEWARE – Another huge consideration for rescuers is stored energy! Sometimes what sounds like a simple solution (such as turning off a machine) can do more harm IF the machine normally recycles before coming to a resting position. OSHA identifies these hazards and provides a pretty good list of examples to be aware of when responding. It includes stored or residual energy in capacitors, springs, elevated machine members, rotating flywheels, hydraulic systems, and air, gas, steam, or water pressure, etc. Rescuers need equipment and techniques to control, restrain, dissipate, and immobilize these hazards.

Machine entrapment rescues are another all too common situation in which responders need to isolate the area at the point of contact with the patient to prevent further movement. RESCUERS BEWARE – Another huge consideration for rescuers is stored energy! Sometimes what sounds like a simple solution (such as turning off a machine) can do more harm IF the machine normally recycles before coming to a resting position. OSHA identifies these hazards and provides a pretty good list of examples to be aware of when responding. It includes stored or residual energy in capacitors, springs, elevated machine members, rotating flywheels, hydraulic systems, and air, gas, steam, or water pressure, etc. Rescuers need equipment and techniques to control, restrain, dissipate, and immobilize these hazards.

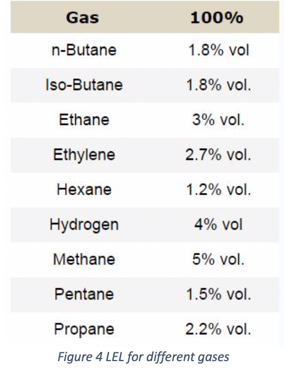

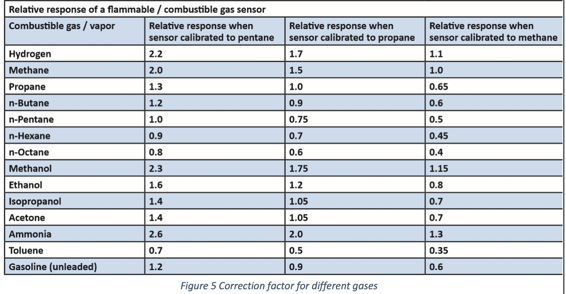

The reason pentane is sometimes used for calibration is that it overestimates the actual LEL. The caveat is that if the meter is poisoned for methane, a methane bump test is indicated.

The reason pentane is sometimes used for calibration is that it overestimates the actual LEL. The caveat is that if the meter is poisoned for methane, a methane bump test is indicated.