The U.S. Department of Labor issues an OSHA National News Release that announces new enforcement guidelines that could exponentially increase penalties for companies who prioritize profits over safety. Specifically, OSHA addresses the expanded application of instance-by-instance citations and non-grouping of violations in certain cases that will go into effect on March 27th of this year.

Originally published in October 1990, CPL 02-00-080, also known as the “egregious or violation-by-violation penalty procedure,” was intended to “create large aggregate penalties” for willful citations in order to “provide an incentive to employers to prevent safety and health violations in their workplace”. In the first memo, OSHA expands the scenarios that “instance-by-instance” citations may be issued for “high-gravity serious violations of standards specific to falls, trenching, machine guarding, respiratory protection, permit-required confined spaces, lockout tagout, and other-than-serious violations specific to recordkeeping”. If you haven’t noticed, these closely align with OSHA’s “Top 10 Most Frequently Cited Standards”. The scope of this directive applies to general industry, construction, maritime, and agriculture; in other words, this applies to everything under OSHA’s jurisdiction.

So, what does the expanded use for instance-by-instance citations include?

According to OSHA, a decision to use instance-by-instance should be based on the consideration of one or more of the following factors and does not preclude the use of other OSHA initiatives, directives, or emphasis programs.

- The employer has received a willful, repeat, or failure to abate violation within the past five years where that classification is current.

- The employer has failed to report a fatality, inpatient hospitalization, amputation, or loss of an eye pursuant to the requirements of 29 CFR 1904.39.

- The proposed citations are related to a fatality/catastrophe.

- The proposed recordkeeping citations are related to injury or illness(es) that occurred as a result of a serious hazard.

This is intended to be a targeted strategy for those employers who repeatedly choose to put profits before their employees’ safety, health and well-being.

According to statements released by Doug Parker, Assistant Secretary for OSHA, “Smart, impactful enforcement means using all the tools available to us when an employer ‘doesn’t get it’ and will respond to only additional deterrence in the form of increased citations and penalties.” He goes on further to state that “This is intended to be a targeted strategy for those employers who repeatedly choose to put profits before their employees’ safety, health and well-being. Employers who callously view injured or sickened workers simply as a cost of doing business will face more serious consequences.”

References

https://www.osha.gov/news/newsreleases/national/01262023-0

https://www.osha.gov/enforcement/directives/cpl-02-00-080

https://www.osha.gov/memos/2023-01-26/application-of-instance-by-instance-penalty-adjustments

https://www.osha.gov/top10citedstandards

https://www.osha.gov/memos/2023-01-26/exercising-discretion-when-not-to-group-violations

https://www.osha.gov/enforcement/directives/cpl-02-00-164/chapter-4

Additional Resources

We are proud to announce that once again Roco has been reapproved as an OSHA VPP Star Worksite organization. VPP Star is the highest level of recognition awarded by OSHA. VPP participants serve as models for other employers, workers, and unions by operating excellent safety and health management programs. Roco has been a VPP Star worksite since 2013 and is excited to continue this tradition of raising the bar on its journey of maintaining an excellent safety and health program.

We are proud to announce that once again Roco has been reapproved as an OSHA VPP Star Worksite organization. VPP Star is the highest level of recognition awarded by OSHA. VPP participants serve as models for other employers, workers, and unions by operating excellent safety and health management programs. Roco has been a VPP Star worksite since 2013 and is excited to continue this tradition of raising the bar on its journey of maintaining an excellent safety and health program. To our knowledge, we are the only rescue training, services and equipment company to achieve the VPP Star designation. The process of earning and renewing our VPP Star is an important way for us to get external feedback and confirm that we are “walking the walk” as an organization.

To our knowledge, we are the only rescue training, services and equipment company to achieve the VPP Star designation. The process of earning and renewing our VPP Star is an important way for us to get external feedback and confirm that we are “walking the walk” as an organization.

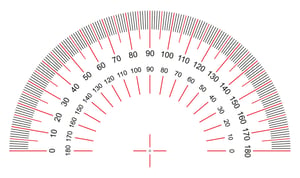

It is not just the degree of slope that tells me what I need to do, it is also the terrain and the condition of the terrain that makes a BIG difference. The terrain AND the slope are going to be major factors in deciding what rope systems to use as well as how many personnel are involved in the rescue. Some examples of terrain that may push you to utilize ropes in a rescue situation would include loose rock/scree, mud, snow, or any other debris that could cause bad footing and an unstable rescue for the patient. Ropes may have to be used to gain access to the victim, to support the team members and the patients during the rescue and remove them from the rescue site.

It is not just the degree of slope that tells me what I need to do, it is also the terrain and the condition of the terrain that makes a BIG difference. The terrain AND the slope are going to be major factors in deciding what rope systems to use as well as how many personnel are involved in the rescue. Some examples of terrain that may push you to utilize ropes in a rescue situation would include loose rock/scree, mud, snow, or any other debris that could cause bad footing and an unstable rescue for the patient. Ropes may have to be used to gain access to the victim, to support the team members and the patients during the rescue and remove them from the rescue site.