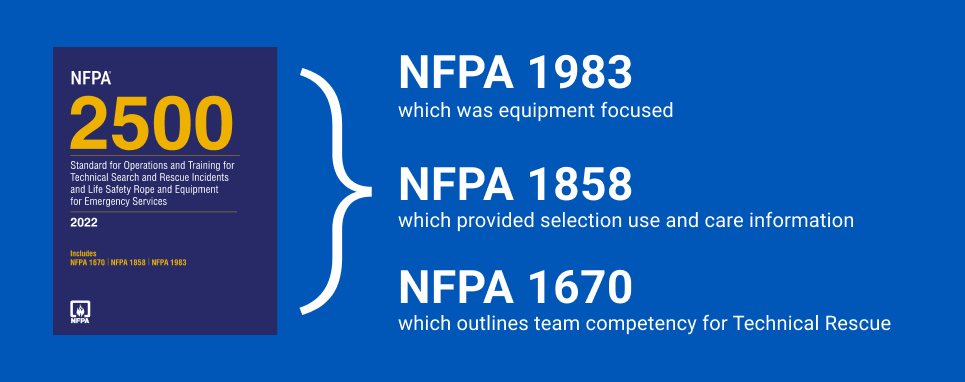

NFPA has started a process of grouping related standards into one volume. For example, it has now grouped NFPA 1983, 1858, and 1670 into one volume, NFPA 2500, “Operations and Training for Technical Search and Rescue Incidents and Life Safety Rope and Equipment for Emergency Services.”

So, NFPA 2500 will include all three of these standards. However, NPFA 1006 “Professional Qualifications for Technical Rescuers” still remains a separate document.

According to a blog post by CEO Loui McCurley of PMI, one of the most noticeable changes will probably be on equipment that will now be marked with NFPA 2500 instead of NFPA 1983. NFPA has decided to include the old standard numbers as a reference. For example, equipment previously would have been marked:

According to a blog post by CEO Loui McCurley of PMI, one of the most noticeable changes will probably be on equipment that will now be marked with NFPA 2500 instead of NFPA 1983. NFPA has decided to include the old standard numbers as a reference. For example, equipment previously would have been marked:

NFPA 1983 (2017 ED)

It will now look more like this…

NFPA 2500 (1983) 2022 ED

There will be a “G”, “T” or “E” to indicate General Use, Technical Use or Escape.

The big change is that as of Spring 2023, manufacturers must stop selling equipment marked to the 2017 edition of 1983. Retailers will still be able to sell the equipment until their stocks are depleted.

Your next question might be, “Will users be required to switch to the new NFPA 2500 marked equipment?” Or, “When must I stop using NFPA 1983 marked equipment?”

There is no NFPA requirement that says you have to use or buy equipment meeting the most current version of any standard. Ms. McCurley indicates that the good news is that there were not significant technical changes to the standard, so most all equipment properly certified to NFPA 1983 (2017) will also meet the NFPA 2500 (2022) standard.

Thank you to Loui McCurley, CEO of PMI, for providing the reference material here. Several videos about this topic are available at www.pmirope.com.

Additional Resources

Your company has a strong safety culture with outstanding employee participation. Everyone is committed to safety and goes out of their way to do things in the safest way possible. As a safety professional, everything is great in your world until suddenly, a “near-miss” report lands on your desk. Supervisors, managers, and company executives are now concerned, worried, or even stressed out about the fact that something unsafe just happened at their company! Many would-be quick to speculate that a near miss is a bad thing; however, as a safety professional, you know that this is not necessarily the case. The reality is, a near-miss or “good catch” report can be one of the most valuable tools for improving your company’s safety program.

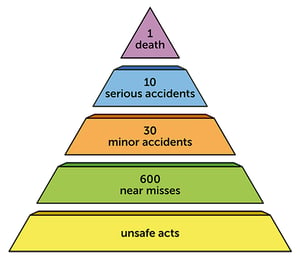

Your company has a strong safety culture with outstanding employee participation. Everyone is committed to safety and goes out of their way to do things in the safest way possible. As a safety professional, everything is great in your world until suddenly, a “near-miss” report lands on your desk. Supervisors, managers, and company executives are now concerned, worried, or even stressed out about the fact that something unsafe just happened at their company! Many would-be quick to speculate that a near miss is a bad thing; however, as a safety professional, you know that this is not necessarily the case. The reality is, a near-miss or “good catch” report can be one of the most valuable tools for improving your company’s safety program. In 1931, Herbert Heinrich published Industrial Accident Prevention: A Scientific Approach where he proposed a concept that would eventually become known as “Heinrich’s Law.” Heinrich’s law states that for every accident that causes a major injury, there are 29 accidents that cause minor injuries and 300 accidents that cause no injury (i.e., near misses).

In 1931, Herbert Heinrich published Industrial Accident Prevention: A Scientific Approach where he proposed a concept that would eventually become known as “Heinrich’s Law.” Heinrich’s law states that for every accident that causes a major injury, there are 29 accidents that cause minor injuries and 300 accidents that cause no injury (i.e., near misses). By performing a root cause analysis, you may learn that it was raining on the day of the near-miss and that the roof in your warehouse has developed a leak, causing a puddle of water to form, creating the unsafe condition that led to the incident. Simply instructing the employee to be more aware of the surroundings may prevent them from slipping again; however, it will not prevent the unsafe condition from reoccurring. The true root cause needs to be addressed; the roof must be repaired.

By performing a root cause analysis, you may learn that it was raining on the day of the near-miss and that the roof in your warehouse has developed a leak, causing a puddle of water to form, creating the unsafe condition that led to the incident. Simply instructing the employee to be more aware of the surroundings may prevent them from slipping again; however, it will not prevent the unsafe condition from reoccurring. The true root cause needs to be addressed; the roof must be repaired. Consider implementing google forms, phone applications, or even a universal near-miss email address. The key is to make the process to submit a near-miss as easy, quick, and painless as possible. For example, many companies now create QR codes that can be scanned, taking personnel right to the form to complete and submit. This can all be done for free with readily available resources around the internet.

Consider implementing google forms, phone applications, or even a universal near-miss email address. The key is to make the process to submit a near-miss as easy, quick, and painless as possible. For example, many companies now create QR codes that can be scanned, taking personnel right to the form to complete and submit. This can all be done for free with readily available resources around the internet. Chris McGlynn is a dynamic safety leader who serves as the Director of Safety at Roco Rescue and is dedicated to amplifying the company's safety success. As a Certified Safety Professional, Confined Space and Rope Rescue Technician, and Paramedic, Chris leverages his expertise to provide employees with the necessary tools, training, and support to work safely and efficiently. He also oversees Roco Safety Services, offering high-caliber safety professionals for special projects and turnarounds. As the VPP Coordinator, Chris ensures that Roco maintains its status as an OSHA VPP Star Worksite, continuing the company’s unwavering commitment to excellence in safety and health. Roco has been an OSHA VPP Star Worksite since 2013.

Chris McGlynn is a dynamic safety leader who serves as the Director of Safety at Roco Rescue and is dedicated to amplifying the company's safety success. As a Certified Safety Professional, Confined Space and Rope Rescue Technician, and Paramedic, Chris leverages his expertise to provide employees with the necessary tools, training, and support to work safely and efficiently. He also oversees Roco Safety Services, offering high-caliber safety professionals for special projects and turnarounds. As the VPP Coordinator, Chris ensures that Roco maintains its status as an OSHA VPP Star Worksite, continuing the company’s unwavering commitment to excellence in safety and health. Roco has been an OSHA VPP Star Worksite since 2013. In a press release, the Village of Westmont said the worker was unresponsive when they were pulled from the underground water main vault at the intersection of 60th Street and Deming Place around 12:40 p.m., about an hour after first responders were called to the scene.

In a press release, the Village of Westmont said the worker was unresponsive when they were pulled from the underground water main vault at the intersection of 60th Street and Deming Place around 12:40 p.m., about an hour after first responders were called to the scene.

Here’s what NFPA 2500 says about cleaning and

Here’s what NFPA 2500 says about cleaning and  Here’s what PMI says about cleaning

Here’s what PMI says about cleaning