Inspect all CMC ProSwivel or Rock Exotica Omni-Block swivel pulleys immediately.

Inspect all CMC ProSwivel or Rock Exotica Omni-Block swivel pulleys immediately.

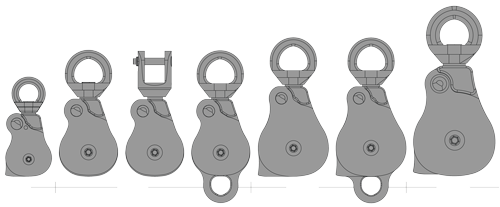

CMC and Rock Exotica, who makes CMC's ProSwivel pulleys, have both issued recall notices on their 1.1" swivel pulleys and SwivaBiner pulleys. The concern is surrounding the set screws that hold the button in. The button secures the side plate, so if the button comes out, the side plate could open and let the rope fall out - which could mean severe injury or death.

The recall only applies to the 1.1" versions manufactured from February 2020 through October 2022, however both manufacturers are recommending that all of these swivel pulleys be inspected.

If you have a pulley subject to the recall, return it to the manufacturer at no charge for inspection/repair. If you purchased your pulleys from Roco, we will be happy to assist you with the recall and inspection.

If you have 1.1" pulleys made outside of the recall window, or have other sizes of any date, you may inspect them yourself or return them for professional inspection.

- 2018 to present

- There should be a dab of epoxy sealant that fills the set screw hole. It may be brownish/yellowish or a white/grey color.

- If the epoxy is missing, return the pulley for repair.

- If the sealant is protruding above the surface, determine the color. If it is white/grey, that's okay. If it is brownish/yellowish, return the pulley for repair.

- 2016 and 2017

- There should be a dab of epoxy sealant like the current models have, but it will only be white/grey. It's okay if it is above the surface of the hole, but if it's missing, return the pulley for repair.

- Prior to 2016

- No visible sealant was used on these models, so don't worry when you see the bare set screw. Just make sure the set screw is even with or below the surface.

- If you are not comfortable doing this inspection yourself, you can send your pulleys to the manufacturer or to Roco for inspection.

- You may want to add your own epoxy to these models to make your daily gear inspections easier. (see details in the inspection notices linked below)

Instructions for identifying your pulleys and locating the serial numbers are included in the manufacturer recall and safety notices. Be sure that you are using the proper notice for your pulley, as the CMC and Rock Exotica serial number locations are slightly different.

Manufacturers' Detailed Information

Note that CMC's and Roco's offices will be closed 12/23/22 through 1/2/23 and reopen Tuesday, January 3rd. However, if you have an urgent need during the holidays, you may reach CMC at info@cmcpro.com and Roco at 800-647-7626 (follow the prompts for emergency after-hours service).

Always remember to inspect your gear before each use. Stay safe, and Merry Christmas!

It is not just the degree of slope that tells me what I need to do, it is also the terrain and the condition of the terrain that makes a BIG difference. The terrain AND the slope are going to be major factors in deciding what rope systems to use as well as how many personnel are involved in the rescue. Some examples of terrain that may push you to utilize ropes in a rescue situation would include loose rock/scree, mud, snow, or any other debris that could cause bad footing and an unstable rescue for the patient. Ropes may have to be used to gain access to the victim, to support the team members and the patients during the rescue and remove them from the rescue site.

It is not just the degree of slope that tells me what I need to do, it is also the terrain and the condition of the terrain that makes a BIG difference. The terrain AND the slope are going to be major factors in deciding what rope systems to use as well as how many personnel are involved in the rescue. Some examples of terrain that may push you to utilize ropes in a rescue situation would include loose rock/scree, mud, snow, or any other debris that could cause bad footing and an unstable rescue for the patient. Ropes may have to be used to gain access to the victim, to support the team members and the patients during the rescue and remove them from the rescue site.

Here are a few examples based on industry use. The fall protection industry generally recommends 2 to 3 years as a service life for a harness or belt in regular use. The Climbing Sports Group of the Outdoor Recreation Coalition of America states that a climbing harness should last about 2 years under normal weekend use. The military uses 7 years as a service life for nylon products. Of course, hard use of any product would call for a shorter service life than would normally be expected

Here are a few examples based on industry use. The fall protection industry generally recommends 2 to 3 years as a service life for a harness or belt in regular use. The Climbing Sports Group of the Outdoor Recreation Coalition of America states that a climbing harness should last about 2 years under normal weekend use. The military uses 7 years as a service life for nylon products. Of course, hard use of any product would call for a shorter service life than would normally be expected