The term “penstock” is one you will hear if you work in the Energy Sector or occasionally in Emergency Response. Those working in the Energy Sector generally have a strong grasp of the term and what it entails. If you work in Emergency Response, can you say the same?

The term “penstock” is one you will hear if you work in the Energy Sector or occasionally in Emergency Response. Those working in the Energy Sector generally have a strong grasp of the term and what it entails. If you work in Emergency Response, can you say the same?

So, what exactly is a penstock? The most common usage of the word is a control structure used in various engineering applications, most commonly in hydropower plants and water distribution systems. It is essentially a large pipe or conduit that controls the flow of water, usually from a higher elevation to a lower elevation. Penstocks are designed to regulate the movement of water, whether for power generation, irrigation, water supply, sewer systems or flood control.

At Roco Rescue, we recently worked with a client who was diligently looking for a solution to protect their employees who would be working in a penstock. This penstock was enormous – 10’ in diameter and 9 miles in length. It presented a multitude of logistical challenges for rescuers, including remote location, internal transportation, communications, ventilation and Lock Out/Tag Out.

As our most experienced rescue technicians worked with our management team on the best approach to providing Confined Space Rescue Standby Services for the job, one of our people remembered a confined space incident in a penstock that occurred 15 years ago. A little research refreshed our memory of the incident that ultimately took the lives of five workers.

The Chemical Safety Board (CSB) investigated the incident and produced an informative video that clearly lays out what went wrong, resulting in the deaths of five individuals.

Click HERE to see video.

(Video provided by the U.S. Chemical Safety Board)

Brad Warr

Brad Warr

The National Fire Protection Association (NFPA) has released the 2022 edition of

The National Fire Protection Association (NFPA) has released the 2022 edition of  As NFPA standards go, one of the first things readers will notice is it is quite comprehensive and thus a very large standard. Regardless, everyone who has any dealings with confined space work should take the time to read and digest it in its entirety. In this article we will provide a high-level overview of the standard as it relates to confined space work and rescue in light of the content with which we are familiar in 1910.146.

As NFPA standards go, one of the first things readers will notice is it is quite comprehensive and thus a very large standard. Regardless, everyone who has any dealings with confined space work should take the time to read and digest it in its entirety. In this article we will provide a high-level overview of the standard as it relates to confined space work and rescue in light of the content with which we are familiar in 1910.146. In addition to these new roles, the standard also directly addresses the hazards associated with lockout/tagout (or lack thereof), and the failure to blind or isolate with the role of Isolation Specialist. An “Isolation Specialist” is the “person responsible for protecting the confined space from the unwanted release of energy (electrical, mechanical, and/or hydraulic), as well as liquids, gases, chemicals, and other materials impacting upon the space.”

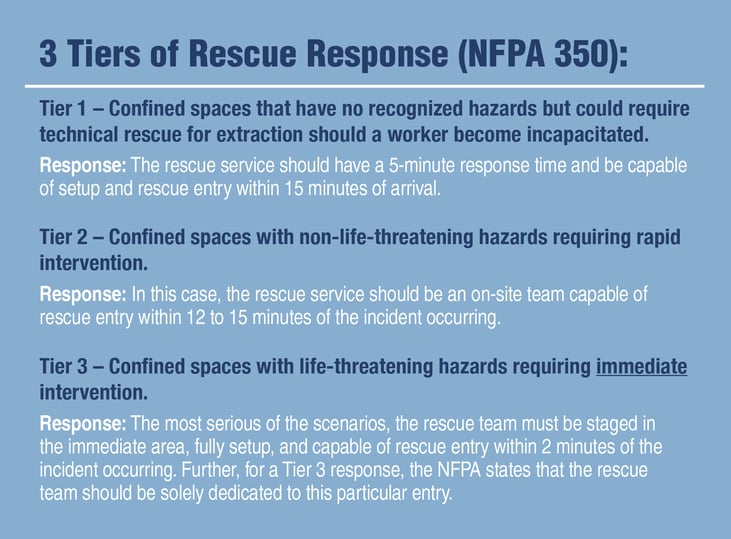

In addition to these new roles, the standard also directly addresses the hazards associated with lockout/tagout (or lack thereof), and the failure to blind or isolate with the role of Isolation Specialist. An “Isolation Specialist” is the “person responsible for protecting the confined space from the unwanted release of energy (electrical, mechanical, and/or hydraulic), as well as liquids, gases, chemicals, and other materials impacting upon the space.” While most of the standard is focused on keeping workers safe and preventing accidents, everyone is cognizant that as long as workers enter confined spaces, there will be accidents where rescue is required. The standard describes both non-entry rescue and entry-type rescue. Regardless of the method selected, the standard stresses the importance of verifying the competency of the rescue services selected. It specifically warns against assuming that all rescue services are prepared for entry-type confined space rescue.

While most of the standard is focused on keeping workers safe and preventing accidents, everyone is cognizant that as long as workers enter confined spaces, there will be accidents where rescue is required. The standard describes both non-entry rescue and entry-type rescue. Regardless of the method selected, the standard stresses the importance of verifying the competency of the rescue services selected. It specifically warns against assuming that all rescue services are prepared for entry-type confined space rescue.

The actual Lombardi quote is much more prophetic.

The actual Lombardi quote is much more prophetic.  Perfect 8’s also have numerous benefits in the field.

Perfect 8’s also have numerous benefits in the field. Brad Warr

Brad Warr