In a grim reminder about the dangers of trench and excavation work, this article from Safety+Health Magazine also serves as a warning to employers. “The court’s decision sends a message to business owners that they can be held criminally accountable and face felony charges if they knowingly fail to protect their workers.”

The owner of Alki Construction LLC has been charged with second-degree manslaughter after an employee was buried while replacing a residential sewer pipe in a trench that had inadequate shoring and was missing a ladder.

Remember to ensure that you have a properly trained Trench Competent Person on site, and check out OSHA's Trenching and Excavation Safety Fact Sheet as a reminder when scheduling trench work.

The learning takeaway for rescuers is to deepen your knowledge.

The learning takeaway for rescuers is to deepen your knowledge.

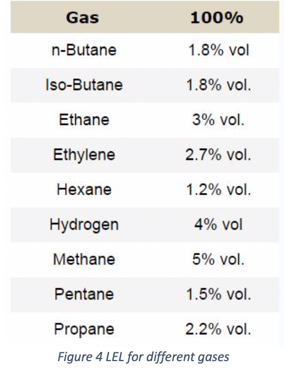

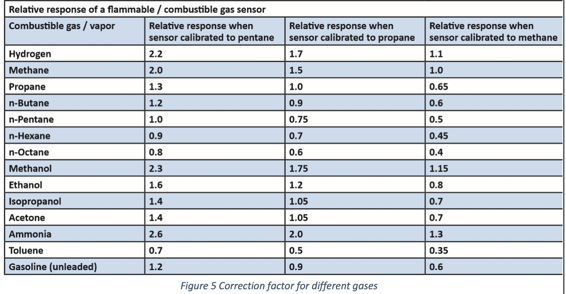

The reason pentane is sometimes used for calibration is that it overestimates the actual LEL. The caveat is that if the meter is poisoned for methane, a methane bump test is indicated.

The reason pentane is sometimes used for calibration is that it overestimates the actual LEL. The caveat is that if the meter is poisoned for methane, a methane bump test is indicated.