By Josh (JC) Hill, Roco Technical Equipment Manager & Chief Instructor

As mentioned in our original story, the alarming statistic of confined space fatalities still proves to be accurate – approximately 60% of fatalities in multi-casualty incidents are the “would be rescuers.” In January, it happened once again. Four construction workers had entered a drainage manhole to determine why the newly paved road was settling in that location.

As mentioned in our original story, the alarming statistic of confined space fatalities still proves to be accurate – approximately 60% of fatalities in multi-casualty incidents are the “would be rescuers.” In January, it happened once again. Four construction workers had entered a drainage manhole to determine why the newly paved road was settling in that location.

Upon entering the space, which is believed to have been done without initial monitoring or ventilation, the worker collapsed. As is seen much too often, a second worker entered the space to assist the downed worker and was rendered unconscious. A third worker entered the space and again succumbed to the atmosphere.

The 911 system was activated and responders from the Key Largo VFD arrived at the scene and prepared to enter the space to perform rescue. Initial reports state that a volunteer firefighter donned an SCBA for respiratory protection and attempted to enter the manhole. He found the space to be too confining and removed his SCBA to make entry. He was in the space for approximately 20 seconds prior to being overtaken by the atmosphere. Note: It is our understanding that proper monitoring of the confined space had still not occurred at the time of the firefighter’s entry to attempt rescue.

Another firefighter then entered the space and recovered the first firefighter from the deadly space. Medical attention was provided until he was airlifted to Jackson Memorial Hospital’s Ryder Trauma Center. The Miami-Dade County Haz-Mat Team was also called to the scene.

After proper monitoring of the space, it was determined that rescue was no longer a viable option and that the scene would be transitioned to recovery efforts. The testing of atmospheric conditions showed the space contained significant levels of hydrogen sulfide and methane gas with decreased levels of oxygen.

Although original reports did not give indication of toxic gases, the signs surrounding the events make it obvious that the potential was there. To have several workers enter a space like this and rendered unconscious in short periods of time is a classic scenario involving atmospheric hazards. This combined with several statements from neighbors that the area smelled of “rotten eggs” for months provide significant clues to atmosphere being a significant contributing factor to the emergency.

So, why do these confined spaces incidents continue to occur across the nation with emergency responders?

When you break it down, the reasons are fairly simplistic and very alarming. Most citizens have a misconception of fire departments and emergency responders. Most often, it is assumed that if you call the fire department, whether in a large municipality or small township, the personnel responding will be qualified and equipped to perform any task needed.

Fact is the vast majority of fire departments are trained and equipped to perform basic first aid and life support along with standard firefighting operations.Funding has and will continue to be the major handicapping factor that limits the capabilities of these agencies. Unfortunately, it usually takes a catastrophic event before funding is provided.

Also, unless dedicated specialty teams are established, it is practically impossible for agencies to train each individual to a proficient level for technical rescue and hazardous material response and have them maintain this level without regular, on-going training. It is also unrealistic for departments to outfit each individual responding unit with all of the necessary equipment to respond to every conceivable scenario.

As we all know, emergency responders are built around running towards the danger when human life is at risk. This attitude is what separates them from the average population and makes them successful at protecting life and property.However, when not properly trained to react and respond to these types of uncommon hazards, the results are often as unfortunate as what we witnessed in Key Largo.

So, how can we change these alarming statistics for emergency responders?

First of all, it is critical that responders understand the unseen hazards they could be exposed to during these types of hazardous confined space operations. It is imperative that all personnel – from the newest rookie to the incident commander – understand what they are facing. Emergency responders must be able to recognize when they are not adequately trained or equipped for an event or hazard. They must understand that their lives are on the line in these hazardous environments.

Firefighters, from the smallest volunteer departments to the largest municipalities, must be trained to recognize the signs of hazardous environments and understand that they would be putting themselves in grave danger if they proceed with rescue attempts. Supervisory personnel should receive additional training that provides the knowledge to understand their full capabilities when facing scenarios they are not properly trained and equipped to safely handle. To stand-down is the wisest decision to protect their personnel from severe injury or death when the chances of successfully performing rescue have little to no chance for success.

It’s a difficult choice – risk vs. reward. But it’s a critical decision that emergency responders must make every day. Their personal safety must come first – it must be a viable rescue before they put themselves in harm’s way.

KEY LARGO, Fla. - Three workers in the Florida Keys died Monday morning (Jan 16) after they were overcome by fumes, authorities said. Miami-Dade Fire Rescue officials said they responded to reports of three people down. The victims were working at a road project.

KEY LARGO, Fla. - Three workers in the Florida Keys died Monday morning (Jan 16) after they were overcome by fumes, authorities said. Miami-Dade Fire Rescue officials said they responded to reports of three people down. The victims were working at a road project.

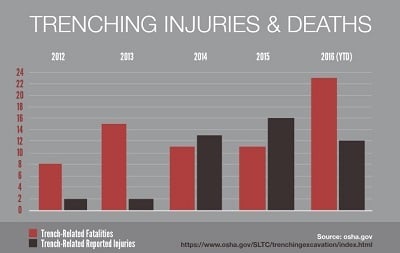

The new OSHA statistics show in 2016, we have two people a month dying in trenches, which is double the amounts for 2014 & 2015. Why, is the soil getting more dangerous? I can only speak to what I have seen in trends in industry that may be contributing to this rise. In previous articles, I have discussed the subject of trench and trench rescue and some of the following concerns:

The new OSHA statistics show in 2016, we have two people a month dying in trenches, which is double the amounts for 2014 & 2015. Why, is the soil getting more dangerous? I can only speak to what I have seen in trends in industry that may be contributing to this rise. In previous articles, I have discussed the subject of trench and trench rescue and some of the following concerns:

“A Trench is a Trench is a Trench”

“A Trench is a Trench is a Trench” One minute a worker was working in the 8-foot trench below ground. The next, he was being buried in it. His co-workers came to his rescue, digging him out with their bare hands. Moments after they pulled the injured man to safety, the unprotected trench collapsed again. His injuries were serious and led to his hospitalization.

One minute a worker was working in the 8-foot trench below ground. The next, he was being buried in it. His co-workers came to his rescue, digging him out with their bare hands. Moments after they pulled the injured man to safety, the unprotected trench collapsed again. His injuries were serious and led to his hospitalization.