![]() Here's a question for the Roco Tech Panel from one of our readers.

Here's a question for the Roco Tech Panel from one of our readers.

I recently became the ERT trainer. I have introduced the Petzl descender to the group and they love it. The question was brought up about the rating for lowering and raising of patients. What is it limits and can it be used in hauling up a two-person load? The max load the manufacturer says is around 600 pounds, and I am not sure if this is enough to meet what NFPA says. I really enjoyed the video Roco put out on this device, and would really enjoy seeing more on on other equipment.

Answer from the Tech Panel: Yes, you can use the Petzl ID-L (ID with red side plates that is NFPA G-rated) for raising and lowering two-person loads. For the ID-L, 600 lbf. is the “design load-rating requirement” for NFPA 1983 General Use. There are also two other ID versions – one with a yellow/gold side plate (ID-S) that is designed for smaller diameter ropes; and a blue side plate version, which will handle ½” rope like the red side plate but with a 550 lbf. design load.

So, what is the design load? Typically, it is the amount of weight/force a device or a system can handle; or the load that it is designed to handle. Once it has met the design load requirement for NFPA, it is placed in an equipment category and tested accordingly. In the case of the ID, it is tested as a descent control device. According to NFPA, General Use descent control devices shall withstand a minimum test load of at least 22 k/N (4946 lbf) without failure. I know what you’re thinking, “Hey, that’s not anywhere near the 9000 lbf we’re used to hearing for General Use?” NFPA requires that rope and carabiners be rated at 8992 lbf with pulleys and some other auxiliary items at 8093 lbf. Rope grab device shall withstand a minimum test load of at least 11 k/N (2473 lbf) without sustaining permanent damage to the device or rope to meet General Use. So, there is a wide range of strength requirements in NFPA 1983 depending on what category an item is tested in.

So, what is the design load? Typically, it is the amount of weight/force a device or a system can handle; or the load that it is designed to handle. Once it has met the design load requirement for NFPA, it is placed in an equipment category and tested accordingly. In the case of the ID, it is tested as a descent control device. According to NFPA, General Use descent control devices shall withstand a minimum test load of at least 22 k/N (4946 lbf) without failure. I know what you’re thinking, “Hey, that’s not anywhere near the 9000 lbf we’re used to hearing for General Use?” NFPA requires that rope and carabiners be rated at 8992 lbf with pulleys and some other auxiliary items at 8093 lbf. Rope grab device shall withstand a minimum test load of at least 11 k/N (2473 lbf) without sustaining permanent damage to the device or rope to meet General Use. So, there is a wide range of strength requirements in NFPA 1983 depending on what category an item is tested in.You must also consider that NFPA 1983 is a manufacturer’s standard and provides strength requirements for equipment to be classified as (T)-Technical Use (300lbf working load) – or (G)-General Use (600lbf working load). Rescuers must also refer to the manufacturer’s recommendations for use. However, an NFPA 1983 G-rating provides a quick field reference to the working load and confirms that a piece of equipment has been tested accordingly. This is important because OSHA will most likely look at this if there is an incident.

To answer your question, the manufacturer (Petzl) allows the ID to be used for the lowering and raising of two-person loads. If you have any other questions or need more information, please let us know – we’ll be glad to help. Check out our latest additions to our Video Resources for other great information!

Reviewed by Pat Furr, Roco Chief Instructor/Technical Consultant

Reviewed by Pat Furr, Roco Chief Instructor/Technical Consultant

By Pat Furr, Roco Chief Instructor/Technical Consultant

By Pat Furr, Roco Chief Instructor/Technical Consultant "If it's been a while since you've updated your rescue equipment kit or attended a rescue class, you may not be aware of some of the newer pieces of rescue gear that not only make your job safer, but make it easier and more efficient as well. The last decade has seen an explosion of emerging technologies that have allowed the design and manufacture of some really exciting and practical equipment. In the coming weeks, we will be reviewing some of the newer gear that you may not have had the opportunity to work with. Hopefully, this will provide the stimulus for you to get out there and find out what else you may be missing out on." Pat Furr, Roco Chief Instructor/Technical Consultant

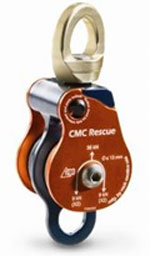

"If it's been a while since you've updated your rescue equipment kit or attended a rescue class, you may not be aware of some of the newer pieces of rescue gear that not only make your job safer, but make it easier and more efficient as well. The last decade has seen an explosion of emerging technologies that have allowed the design and manufacture of some really exciting and practical equipment. In the coming weeks, we will be reviewing some of the newer gear that you may not have had the opportunity to work with. Hopefully, this will provide the stimulus for you to get out there and find out what else you may be missing out on." Pat Furr, Roco Chief Instructor/Technical Consultant The feature of the Omni-Block that I think is as important as the built-in swivel is the "quick release side plate." This proprietary design allows the rope to be loaded andunloaded into the pulley without having to remove the pulley from the anchor. Depending on the application, this provides a new level of ease for systems incorporating temporary directional pulleys, and really reduces the chance that gear may be dropped. This is especially important for rescuers that are building systems while at height, such as with tower rescue operations.

The feature of the Omni-Block that I think is as important as the built-in swivel is the "quick release side plate." This proprietary design allows the rope to be loaded andunloaded into the pulley without having to remove the pulley from the anchor. Depending on the application, this provides a new level of ease for systems incorporating temporary directional pulleys, and really reduces the chance that gear may be dropped. This is especially important for rescuers that are building systems while at height, such as with tower rescue operations.