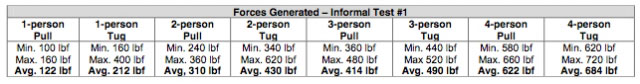

In this and upcoming articles, we want to give you an idea of the actual forces that are put on M/A systems versus theoretical forces that you may read about. What’s the difference?

In this and upcoming articles, we want to give you an idea of the actual forces that are put on M/A systems versus theoretical forces that you may read about. What’s the difference?

With theoretical, we’re referring to the amount of force that is “supposed” to be produced, while the actual is just that…the actual amount of force that is produced when the system is built and operated.

For example, calculating the force if you built a 3:1 mechanical advantage “on paper” (theoretically) versus physically building the system. With the actual system, you would have to consider the friction loss created by the system components, so the “actual M/A” may be 2.5:1 with the same 3:1 system.

Test #1: Straight-line Pull

Student Set-up: Students were asked to pull on the line in a horizontal plane and exhibit as much force as they could without tugging/jerking the line. They were then asked to maintain that tension and tug/jerk the line.Equipment Set-up: 12-ft of 1⁄2” PMI rope tied with a Figure 8 knot and attached to the dynamometer by two 2-ft pieces of 1” basket-looped webbing and two auto-locking steel carabiners to a rigid anchor with another basket-looped webbing loop.

What the Numbers Mean

First of all, they will serve as a baseline for future informal tests when comparing different types of M/A systems. We will evaluate the efficiency of the different systems as well as the possible forces that are put on the components of the system when using typical rescue haul teams.Grasping at Ropes

One interesting fact that we can take away from these numbers is that even though the vast majority of the persons involved in the testing (random rescue students) weighedin excess of 160 lbs, they were only able to generate a maximum of 160 pounds of force on the 1⁄2-inch rope. This is largely due to the student’s ability to grasp and hold onto the 1⁄2” line before it pulled through their hands.

One interesting fact that we can take away from these numbers is that even though the vast majority of the persons involved in the testing (random rescue students) weighedin excess of 160 lbs, they were only able to generate a maximum of 160 pounds of force on the 1⁄2-inch rope. This is largely due to the student’s ability to grasp and hold onto the 1⁄2” line before it pulled through their hands.Similar tests using 9mm rope had an average force of 120 lbf for a single-person pull. There was only a slight difference of about 2 lbf between the 1⁄2-inch rope and the 9mm rope. We had anticipated a greater disparity as the rope diameter decreased and the ability to grasp the smaller line was lessened. However, we did observe that with the smaller diameter rope, haulers had a tendency to twist their hands making a 90-degree turn in the rope. This added additional friction making it possible to put more force on the line before it slipped.

Stay tuned as we continue this informal, real-world testing in future blog posts. It should be interesting to see how the forces translate from 1,2,3, and 4-person Haul Teams when using these various Mechanical Advantage systems.

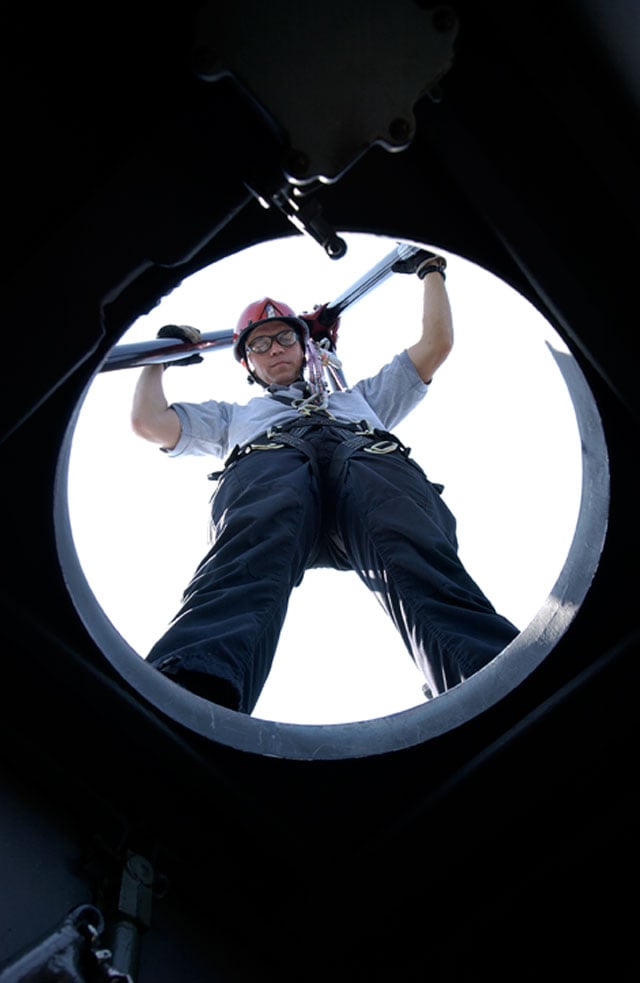

1. One of the first things is to identify and categorize the space as “permit-required” or “non-permit required.” You’ll need to carefully consider the possible hazards based on the information gathered.

1. One of the first things is to identify and categorize the space as “permit-required” or “non-permit required.” You’ll need to carefully consider the possible hazards based on the information gathered. Since 1999, Roco has had the opportunity to train and equip rescue teams in Kuwait. The first team that we trained was the Kuwait National Petroleum Corporation (KNPC) Fire Officers that were assigned to three refineries located south of Kuwait City. In 2001, Ratqa Contracting was tasked with providing a Technical Rescue Team at the same refineries and Roco provided the Technician Level training for this new team.

Since 1999, Roco has had the opportunity to train and equip rescue teams in Kuwait. The first team that we trained was the Kuwait National Petroleum Corporation (KNPC) Fire Officers that were assigned to three refineries located south of Kuwait City. In 2001, Ratqa Contracting was tasked with providing a Technical Rescue Team at the same refineries and Roco provided the Technician Level training for this new team. The Ratqa Rescue Team on duty at the time of the incident was located approximately 10 minutes away at a neighboring refinery. Immediately, the Rescue Team Leader terminated their current standby operations and responded within 6 minutes to the scene by utilizing a “short cut” which minimized response time by 4 minutes.

The Ratqa Rescue Team on duty at the time of the incident was located approximately 10 minutes away at a neighboring refinery. Immediately, the Rescue Team Leader terminated their current standby operations and responded within 6 minutes to the scene by utilizing a “short cut” which minimized response time by 4 minutes. "The concept of LOTO is a great one and it works. As rescuers, we have to take the common industrial application and expand it to ensure that the rescue scene is safe and that we are controlling hazards at the point of contact with the victim or in a space where something has gone very wrong," says Dennis O'Connell, Chief Instructor and Director of Training for Roco Rescue.

"The concept of LOTO is a great one and it works. As rescuers, we have to take the common industrial application and expand it to ensure that the rescue scene is safe and that we are controlling hazards at the point of contact with the victim or in a space where something has gone very wrong," says Dennis O'Connell, Chief Instructor and Director of Training for Roco Rescue.  Unlike standard LOTO, which is usually a systems’ approach, rescuers are generally trying to control the environment near an entrapped victim. As rescuers, we often act outside the parameters of a LOTO procedure that may already be in place. Because rescuers would best be defined under “affected employees” in a rescue where a LOTO procedure is in place, we need to understand what OSHA CFR 1910.147(b) says about “authorized employees” and “affected employees.”

Unlike standard LOTO, which is usually a systems’ approach, rescuers are generally trying to control the environment near an entrapped victim. As rescuers, we often act outside the parameters of a LOTO procedure that may already be in place. Because rescuers would best be defined under “affected employees” in a rescue where a LOTO procedure is in place, we need to understand what OSHA CFR 1910.147(b) says about “authorized employees” and “affected employees.” Pat Furr reviews the importance of following OSHA safety standards for fall protection, and the steps an employer can take to ensure a safe work environment by providing high quality training. In the recent article by Mark Stromme, published in ISHN and on this blog, he addresses several myths regarding compliance with OSHA Fall Protection in the construction industry. Fact is, this wisdom applies to industry across the board.

Pat Furr reviews the importance of following OSHA safety standards for fall protection, and the steps an employer can take to ensure a safe work environment by providing high quality training. In the recent article by Mark Stromme, published in ISHN and on this blog, he addresses several myths regarding compliance with OSHA Fall Protection in the construction industry. Fact is, this wisdom applies to industry across the board.  One of the most important steps an employer can take towards developing an effective comprehensive fall protection program is to provide top quality training to their selected fall protection competent persons. By selecting the right person(s) for this position, the employer is assigning a degree of authority and expectations that the competent person will be very well versed in all there is to know about fall protection.

One of the most important steps an employer can take towards developing an effective comprehensive fall protection program is to provide top quality training to their selected fall protection competent persons. By selecting the right person(s) for this position, the employer is assigning a degree of authority and expectations that the competent person will be very well versed in all there is to know about fall protection.