My team has always attended the Roco Industrial I/II, will team members attending the new Urban/Industrial Rescue Essentials™ course have difficulty fitting in with the team?

Not at all. The concept of the Urban/Industrial Rescue Essentials™ course is still focused around producing a well-rounded, proficient rescuer. The primary differences you will notice center around streamlining the techniques utilized by rescuers to be more proficient in “must have” skills, use of updated equipment created through advances in technology, and performing as a member of a team. One of the primary reasons for the course evolving is to provide students with the ability to return as a better TEAM MEMBER and not just a proficient rescuer.

Not at all. The concept of the Urban/Industrial Rescue Essentials™ course is still focused around producing a well-rounded, proficient rescuer. The primary differences you will notice center around streamlining the techniques utilized by rescuers to be more proficient in “must have” skills, use of updated equipment created through advances in technology, and performing as a member of a team. One of the primary reasons for the course evolving is to provide students with the ability to return as a better TEAM MEMBER and not just a proficient rescuer.

– Chief Instructor Troy Gardner

I previously attended an Industrial I/II course, but it has been several years. What are some of the differences the Urban/Industrial Rescue Essentials course provides?

There are several noticeable differences you will find in the Urban/Industrial Rescue Essentials course. The biggest difference you will notice is with the equipment utilized during training. The technological advances in rescue equipment over the last several years are impressive to say the least and offer a safe and more efficient approach to rescue.

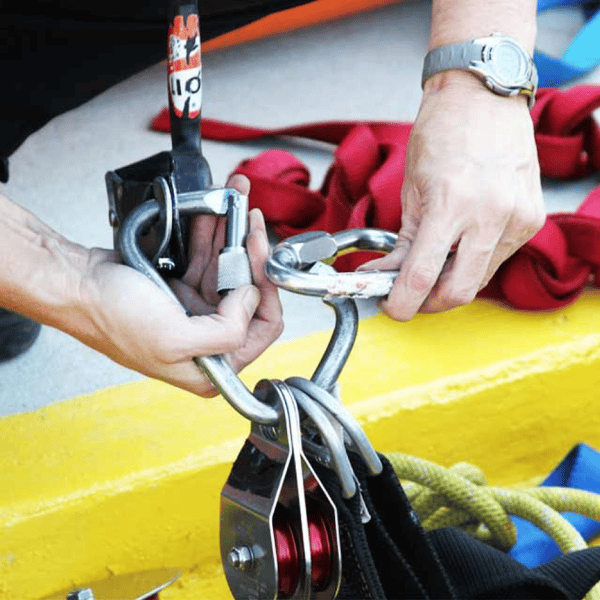

For example, the Petzl I’D has been the staple of rescue operations for two decades now. It is hard to find a rescue team that does not utilize the I’D as their primary device, or at least knows of its capabilities. Petzl introduced the Maestro in 2020 which dramatically increased the efficiency of our rescue systems with an intuitive design and ease of functionality that makes it well-received by the beginner and the experienced rescuer alike. Also, devices like the ASAP Lock fit the need of being an engineered safety device while increasing the efficiency and reliability of the operator.

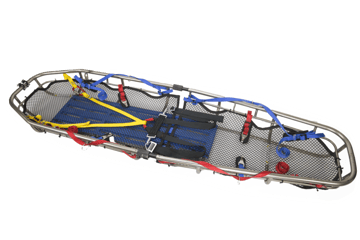

We also recognized, through input from our instructors, that rescuers would benefit by replacing skills that required continuous practice, such as diamond lashing for patient packaging, with manufactured systems like CMC’s Patient Tie-in System. This allows new rescuers the ability to gain confidence and proficiency by using a simple system vs. trying to absorb more advanced skills and still perform the tasks.

Our instructors also recognized the need for students new to rescue to gain a true understanding of how important proper belaying is for safety. To build proficiency in this skill, students are required to “belay a falling load” where they learn the skills necessary to safely and effectively “catch” the load using various techniques.There are several other exciting changes we have made that will benefit the student and produce a higher level of rescuer.

– Director of Training Chris Carlsen

I work at a fire department that does not respond to any industrial facilities. Would I benefit from attending the Urban/Industrial Rescue Essentials course?

Choosing the right rescue class can be a daunting task. At Roco Rescue, our instructor cadre is well represented by the fire service and would like to include a few questions for you to think about when determining which course you should attend.

Choosing the right rescue class can be a daunting task. At Roco Rescue, our instructor cadre is well represented by the fire service and would like to include a few questions for you to think about when determining which course you should attend.

- Does your response area have multiple story structures that could present difficulties assisting occupants during emergencies using standard means of egress?

- Do road crews, utility workers or telecommunication industries in your area perform activities above and/or below ground?

- Have you ever packaged a patient onto a backboard in a cluttered back bedroom and struggled to get them out? only to find that moving the now boarded patient will be extremely difficult utilizing traditional means?

- Have you ever pushed your SCBA personal skills to their limits in really tight spaces?

- Has your crew struggled to move a heavy load that left you wondering if there was an easier way?

If you have ever had any of these questions come up, or one of the many other related questions that apply to fire departments across the globe, then Roco’s Urban/Industrial Rescue Essentials should be at the top of your list. It addresses both the needs of municipal (urban) rescue as well as that of industrial or manufacturing facilities.

– Chief Instructor Brad Warr

The Industrial I/II course was already a full week with a lot to learn. Will my team members struggle to keep up in the new program?

Not at all. In fact, we believe you will have rescue team members returning to your organization with a higher level of retention than ever before. There are some incredible new advancements in equipment and techniques out there, which make it even easier for the novice to acquire the skills to become a proficient rescuer.

Not at all. In fact, we believe you will have rescue team members returning to your organization with a higher level of retention than ever before. There are some incredible new advancements in equipment and techniques out there, which make it even easier for the novice to acquire the skills to become a proficient rescuer.

Urban/Industrial Rescue Essentials™ has been streamlined to provide a stronger emphasis on key areas of instruction. We have also incorporated numerous improvements in teaching methodology as recommended by our most experienced Roco instructors. This allows students to gain more repetitions in needed skills and retain a higher level of information.

Our goal is to make a better, more prepared rescuer. We believe the new Urban/Industrial Rescue Essentials™ from Roco will do just that.

– Chief Instructor Eddie Chapa

Will sending our rescue team members to the Urban and Industrial Essentials course meet OSHA requirements for confined space rescue?

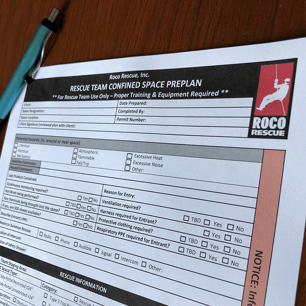

Although OSHA does not provide a specific checklist of the skills or exact performance objectives required to be deemed a competent rescuer, 1910.146 Permit Required Confined Spaces does give us some guidance of what a rescuer should be. In 1910.146 (k)(1)(iii)(A) it states that a rescuer shall “Have the ability to reach the victim(s) within a time frame that is appropriate for the permit space hazards(s) identified”. 1910.146(k)(1)(iii)(B) further states that the rescuer shall be “equipped for and proficient in performing the needed rescue services”.

Although OSHA does not provide a specific checklist of the skills or exact performance objectives required to be deemed a competent rescuer, 1910.146 Permit Required Confined Spaces does give us some guidance of what a rescuer should be. In 1910.146 (k)(1)(iii)(A) it states that a rescuer shall “Have the ability to reach the victim(s) within a time frame that is appropriate for the permit space hazards(s) identified”. 1910.146(k)(1)(iii)(B) further states that the rescuer shall be “equipped for and proficient in performing the needed rescue services”.

The Roco Essentials™ course is designed for developing a rescuer who is confident and proficient in the skills necessary to perform rescues in both urban and industrial environments. This ensures that students will be able to return to their team and execute the required tasks necessary to expedite rescue efforts safely and effectively.

OSHA 1910.146(k)(1)(ii) also requires that the host employer “evaluate” a rescue team’s ability – in terms of proficiency with rescue-related tasks and equipment, and the ability to function appropriately while rescuing entrants from the particular permit space or types of permit spaces identified. Urban/Industrial Rescue Essentials courses conducted at the Roco Training Center provide students with realistic scenarios from all six (6) confined space types, including elevated vessels and towers. The course also includes simulated rescue from IDLH atmospheres requiring the use of SCBA. These scenarios can be used to document a team’s practice requirements listed under 1910.146.

– Director of Training Chris Carlsen

I would really like to send our team members to a Roco certification class, but we do not have the time or funding to dedicate to a Fast-Track course. Is the Urban/Industrial Rescue Essentials course a good compromise?

I would not consider the Roco Essentials™ course a compromise by any means. It is a building block of rescue knowledge that your team can use to create highly proficient rescuers. The course is designed to give the rescuer confidence in many of the skills needed to obtain certification to NFPA 1006 by utilizing a very heavy “hands-on” approach to training. Rescuers who attend the Urban/Industrial Rescue Essentials course not only obtain a high level of proficiency in these skills, but they also gain a great understanding of what it takes to make a Rescue Team effective. Rescuers completing this course can also achieve Rescue Technician certification by attending our Confined Space Rescue Technician course.

I would not consider the Roco Essentials™ course a compromise by any means. It is a building block of rescue knowledge that your team can use to create highly proficient rescuers. The course is designed to give the rescuer confidence in many of the skills needed to obtain certification to NFPA 1006 by utilizing a very heavy “hands-on” approach to training. Rescuers who attend the Urban/Industrial Rescue Essentials course not only obtain a high level of proficiency in these skills, but they also gain a great understanding of what it takes to make a Rescue Team effective. Rescuers completing this course can also achieve Rescue Technician certification by attending our Confined Space Rescue Technician course.

– Chief Instructor Kenny Greene

OSHA 1910.146 Appendix F

OSHA 1910.146 Appendix F