Confined spaces continue to present fatal hazards to workers, and OSHA continues to take notice. While OSHA lists fewer confined space accidents in 2021 than in 2020, 100% of them involved fatalities. the following summaries are from OSHA News Releases. These tragedies serve as reminders to employers and rescuers of the inherent dangers involved in confined space entry. Don't take chances when confined spaces are involved – the cost is simply too high.

8/2/2021 Dallas – Initiative to Protect Workers from Confined Space Dangers1

OSHA Regional Emphasis will target the transportation tank cleaning industry in Texas, Oklahoma, Arkansas, and Louisiana.

This special initiative is designed to focus on industries involving tank cleaning activities, including trucking, rail and road transportation, remediation services, material recovery and waste management services. Transportation tanks on trucks, trailers or railcars require cleaning and inspecting before they are refilled for transport. The workers who clean these tanks risk exposure to toxic vapors from chemicals, decaying crops, waste and other substances, and to asphyxiation, fires and explosions.

The agency reported that a worker cleaning the inside of a tank trailer in Pasadena, Texas, in December 2019 fell victim to hazardous vapors, as did a co-worker who attempted rescue. Then, in August 2020, two workers entered a natural gas tanker on a railcar in Hugo, Oklahoma, and fell victim to its vapors (see the 2/10 release below). Due to these incidents, four lives were lost in the tank cleaning industry in less than a year – a troubling trend of preventable workplace deaths in the region.

“Too often, employers allow workers to enter tanks without testing atmospheric conditions, completing confined space entry permits or providing adequate respiratory protection,” said OSHA Regional Administrator Eric Harbin.

8/2/2021 Chicago – Initiative to Protect Workers in Tank Cleaning Industry from Atmospheric, Confined Space Hazards2

OSHA Regional Emphasis was issued for the Midwest after multiple deaths occurred in tank trucks. The report listed two examples of instances:

- A worker tasked with cleaning a chemical tank trailer collapsed upon entering the tank. Hearing the employee’s call for help, a nearby truck driver entered the tank. Both succumbed to fatal toxic fumes.

- A worker opened the lid of a tanker trailer containing toluene and was found a short time later lying across the open dome and unresponsive. He survived after being treated at a local hospital for respiratory failure and cardiac arrest.

OSHA Chicago reported that 23 deaths and 97 incidents have occurred in the region since 2016. The most common violations included the failure to prevent inhalation of harmful substances and to follow procedures for permit-required confined spaces.

7/23/2021 Georgia – Six Preventable Confined Space Deaths at Poultry Processing Plant3

On January 28, 2021, six workers went to work at a poultry processing plant unaware that they would not be returning home. Just after their shift began, a freezer malfunctioned, releasing colorless, odorless liquid nitrogen that displaced the oxygen in the room.

Three maintenance workers entered the freezer room without precautions – never trained on the deadly effects of nitrogen exposure – and were overcome immediately. Three other workers entered the room and were also overcome. Five of the workers died immediately, a sixth died on the way to the hospital. At least a dozen other workers needed hospital care.

Of the numerous violations, the company failed to perform a hazard assessment for exposure to liquid nitrogen and also failed to implement a permit-required confined space program for workers who entered the freezer. In addition, they did not notify contractors who are required to work inside the liquid nitrogen freezer that it was a permit-required confined space.

3/29/2021 Ohio – Production Facility Cited for Exposing Employees to Dangerous Confined Spaces and other Hazards4

A January 2021 investigation found that machine operators and maintenance employees entered powder-coated ovens routinely without testing atmospheric conditions or securing natural gas lines and operating machine parts. The company also exposed workers to multiple safety and health hazards by failing to designate the ovens as permit-required confined spaces. The employer also failed to isolate natural gas lines and mechanical energy, i.e., lockout/tagout.

“Confined spaces often expose workers to atmospheric and mechanical hazards,” said OSHA Area Director Ken Montgomery. “OSHA has specific regulations for implementing required training and safety procedures to protect workers who must enter confined spaces, including atmospheric testing and ensuring equipment and energy sources are disabled before workers enter these spaces.”

2/10/2021 Oklahoma – Two Confined Space Deaths at Railcar Company5

Here is additional information concerning a railcar incident that was mentioned in the August release above.

A worker entered a natural gas railcar for cleaning on August 12, 2020. He became unresponsive shortly after entering the tank. A second employee entered the space and was also overcome in an attempt to rescue the fallen worker. Both workers were eventually recovered and later pronounced dead at a local hospital.

OSHA found that the company failed to require a permit to allow entry into the railcar, ventilate the space, monitor hazards inside the space and complete entry permits for work inside a confined space. The company was cited for 11 serious violations and two willful violations.

“Work inside confined spaces is a dangerous job and federal workplace safety standards must be followed to avoid disaster,” said OSHA Area Director Steven Kirby. “As is the case here, failing to follow OSHA standards can be the difference between life and death.”

Additional Resources

- Attendant Safety Requirements Poster (pictured here)

- Confined Space Entry Checklist

- Common Causes of Confined Space Fatalities

- Limitations of Atmospheric Monitors

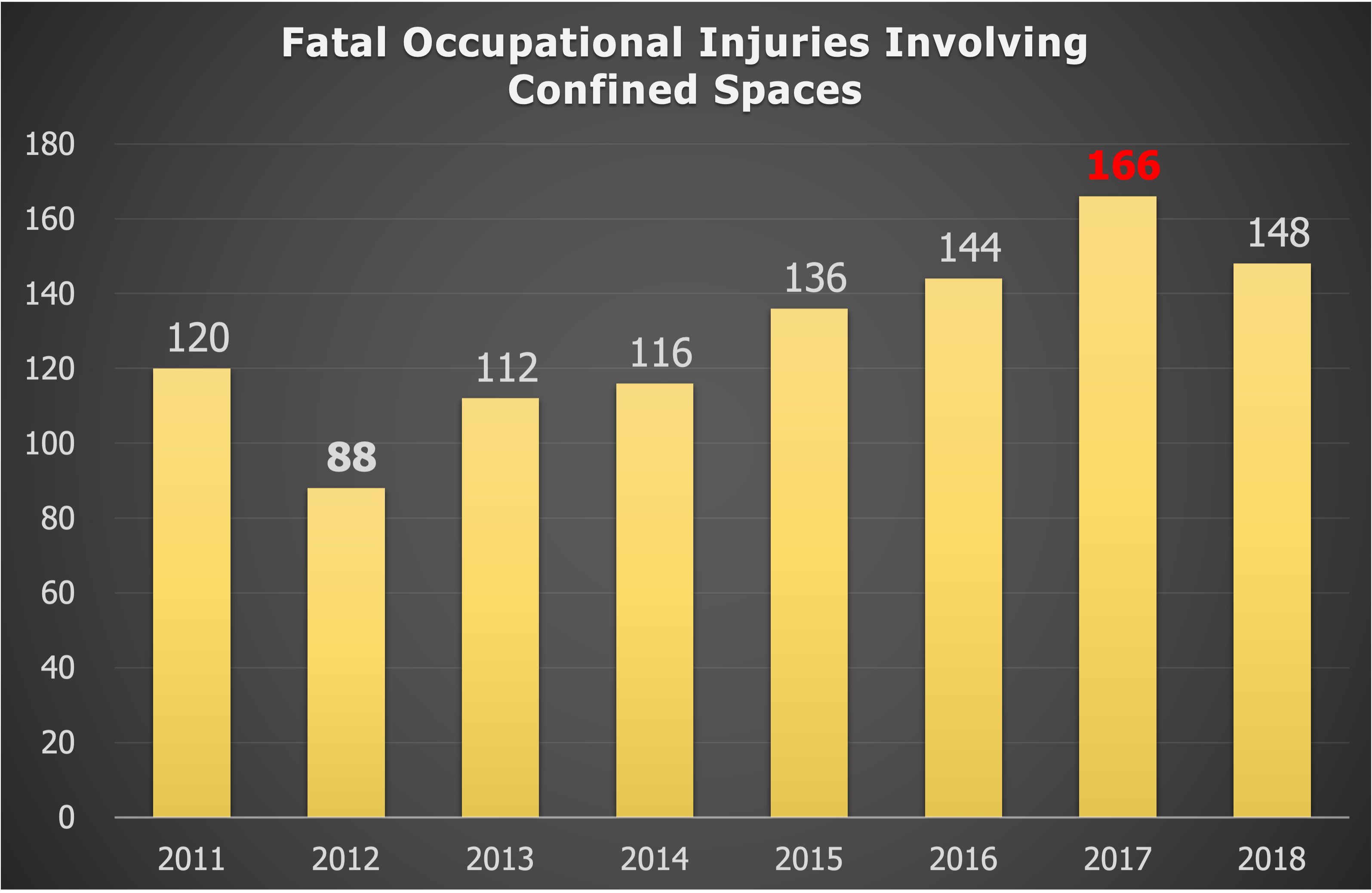

The 2011 to 2018 average was 128 deaths per year, up from 96 in 2005-2009, and the trend was a consistent increase from 2013 through 2017. Only one state (Rhode Island) experienced no confined space fatalities during this period. This is yet another notable increase, as only 28 states recorded fatalities in 2005-2009.

The 2011 to 2018 average was 128 deaths per year, up from 96 in 2005-2009, and the trend was a consistent increase from 2013 through 2017. Only one state (Rhode Island) experienced no confined space fatalities during this period. This is yet another notable increase, as only 28 states recorded fatalities in 2005-2009.

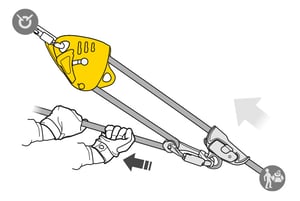

will be a fixture in a rope rescuer’s toolkit. These are critical components of a two-tension system because they provide the three primary functions two-tensioned systems require – friction control, belay, and haul. By providing two mirrored tensioned systems during a lower, the forces on either of the systems are essentially cut in half. This greatly reduces stress on the system and is more easily managed by the operator working with heavier rescue loads.

will be a fixture in a rope rescuer’s toolkit. These are critical components of a two-tension system because they provide the three primary functions two-tensioned systems require – friction control, belay, and haul. By providing two mirrored tensioned systems during a lower, the forces on either of the systems are essentially cut in half. This greatly reduces stress on the system and is more easily managed by the operator working with heavier rescue loads.  Also, as mentioned previously, using a mirrored 3:1 or 5:1 Z-rig through a Maestro or other similar device during hauling operations will double the mechanical advantage compared to using a single haul system. Applying two 3:1 mirrored MAs results in a 6:1 total MA. This can reduce the manpower required for the haul team, which is beneficial for a variety of reasons.

Also, as mentioned previously, using a mirrored 3:1 or 5:1 Z-rig through a Maestro or other similar device during hauling operations will double the mechanical advantage compared to using a single haul system. Applying two 3:1 mirrored MAs results in a 6:1 total MA. This can reduce the manpower required for the haul team, which is beneficial for a variety of reasons.