We were so excited to see all the applicants for our Fire Department Scholarship Program – we decided to pick 10 instead of 1! The following individuals were selected to attend a Roco Urban/Industrial Rescue Essentials™ Course at no charge at the Roco Training Center in Baton Rouge.

Winners:

|

We will be getting in touch with the above individual winners to share the good news and what the next step is.

Roco Rescue hopes that this free training will help broaden the range of skills in confined space and rope rescue for firefighters and their departments.

Roco Rescue hopes that this free training will help broaden the range of skills in confined space and rope rescue for firefighters and their departments.

Click button below if you are interested in applying for the next Fire Department Scholarship Program selection.

Offer valid for USA-based emergency responders only based on space availability. Must be 18 years or older and physically fit to participate in hands-on rescue exercises. Offer is valid for limited time and subject to change without notice.

Your company has a strong safety culture with outstanding employee participation. Everyone is committed to safety and goes out of their way to do things in the safest way possible. As a safety professional, everything is great in your world until suddenly, a “near-miss” report lands on your desk. Supervisors, managers, and company executives are now concerned, worried, or even stressed out about the fact that something unsafe just happened at their company! Many would-be quick to speculate that a near miss is a bad thing; however, as a safety professional, you know that this is not necessarily the case. The reality is, a near-miss or “good catch” report can be one of the most valuable tools for improving your company’s safety program.

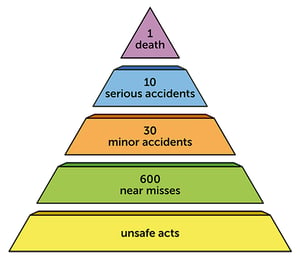

Your company has a strong safety culture with outstanding employee participation. Everyone is committed to safety and goes out of their way to do things in the safest way possible. As a safety professional, everything is great in your world until suddenly, a “near-miss” report lands on your desk. Supervisors, managers, and company executives are now concerned, worried, or even stressed out about the fact that something unsafe just happened at their company! Many would-be quick to speculate that a near miss is a bad thing; however, as a safety professional, you know that this is not necessarily the case. The reality is, a near-miss or “good catch” report can be one of the most valuable tools for improving your company’s safety program. In 1931, Herbert Heinrich published Industrial Accident Prevention: A Scientific Approach where he proposed a concept that would eventually become known as “Heinrich’s Law.” Heinrich’s law states that for every accident that causes a major injury, there are 29 accidents that cause minor injuries and 300 accidents that cause no injury (i.e., near misses).

In 1931, Herbert Heinrich published Industrial Accident Prevention: A Scientific Approach where he proposed a concept that would eventually become known as “Heinrich’s Law.” Heinrich’s law states that for every accident that causes a major injury, there are 29 accidents that cause minor injuries and 300 accidents that cause no injury (i.e., near misses). By performing a root cause analysis, you may learn that it was raining on the day of the near-miss and that the roof in your warehouse has developed a leak, causing a puddle of water to form, creating the unsafe condition that led to the incident. Simply instructing the employee to be more aware of the surroundings may prevent them from slipping again; however, it will not prevent the unsafe condition from reoccurring. The true root cause needs to be addressed; the roof must be repaired.

By performing a root cause analysis, you may learn that it was raining on the day of the near-miss and that the roof in your warehouse has developed a leak, causing a puddle of water to form, creating the unsafe condition that led to the incident. Simply instructing the employee to be more aware of the surroundings may prevent them from slipping again; however, it will not prevent the unsafe condition from reoccurring. The true root cause needs to be addressed; the roof must be repaired. Consider implementing google forms, phone applications, or even a universal near-miss email address. The key is to make the process to submit a near-miss as easy, quick, and painless as possible. For example, many companies now create QR codes that can be scanned, taking personnel right to the form to complete and submit. This can all be done for free with readily available resources around the internet.

Consider implementing google forms, phone applications, or even a universal near-miss email address. The key is to make the process to submit a near-miss as easy, quick, and painless as possible. For example, many companies now create QR codes that can be scanned, taking personnel right to the form to complete and submit. This can all be done for free with readily available resources around the internet. Chris McGlynn is a dynamic safety leader who serves as the Director of Safety at Roco Rescue and is dedicated to amplifying the company's safety success. As a Certified Safety Professional, Confined Space and Rope Rescue Technician, and Paramedic, Chris leverages his expertise to provide employees with the necessary tools, training, and support to work safely and efficiently. He also oversees Roco Safety Services, offering high-caliber safety professionals for special projects and turnarounds. As the VPP Coordinator, Chris ensures that Roco maintains its status as an OSHA VPP Star Worksite, continuing the company’s unwavering commitment to excellence in safety and health. Roco has been an OSHA VPP Star Worksite since 2013.

Chris McGlynn is a dynamic safety leader who serves as the Director of Safety at Roco Rescue and is dedicated to amplifying the company's safety success. As a Certified Safety Professional, Confined Space and Rope Rescue Technician, and Paramedic, Chris leverages his expertise to provide employees with the necessary tools, training, and support to work safely and efficiently. He also oversees Roco Safety Services, offering high-caliber safety professionals for special projects and turnarounds. As the VPP Coordinator, Chris ensures that Roco maintains its status as an OSHA VPP Star Worksite, continuing the company’s unwavering commitment to excellence in safety and health. Roco has been an OSHA VPP Star Worksite since 2013.

We are proud to announce that once again Roco has been reapproved as an OSHA VPP Star Worksite organization. VPP Star is the highest level of recognition awarded by OSHA. VPP participants serve as models for other employers, workers, and unions by operating excellent safety and health management programs. Roco has been a VPP Star worksite since 2013 and is excited to continue this tradition of raising the bar on its journey of maintaining an excellent safety and health program.

We are proud to announce that once again Roco has been reapproved as an OSHA VPP Star Worksite organization. VPP Star is the highest level of recognition awarded by OSHA. VPP participants serve as models for other employers, workers, and unions by operating excellent safety and health management programs. Roco has been a VPP Star worksite since 2013 and is excited to continue this tradition of raising the bar on its journey of maintaining an excellent safety and health program. To our knowledge, we are the only rescue training, services and equipment company to achieve the VPP Star designation. The process of earning and renewing our VPP Star is an important way for us to get external feedback and confirm that we are “walking the walk” as an organization.

To our knowledge, we are the only rescue training, services and equipment company to achieve the VPP Star designation. The process of earning and renewing our VPP Star is an important way for us to get external feedback and confirm that we are “walking the walk” as an organization.