As part of our efforts to support municipal emergency responders, Roco Rescue will be offering quarterly scholarships to our open-enrollment 50-hour Rescue Essentials Courses conducted at the Roco Training Center in Baton Rouge, Louisiana. To be considered, applicants will complete an online form and explain why they are interested in attending a course and how it will benefit them and their department. One student will be selected per quarter.

As part of our efforts to support municipal emergency responders, Roco Rescue will be offering quarterly scholarships to our open-enrollment 50-hour Rescue Essentials Courses conducted at the Roco Training Center in Baton Rouge, Louisiana. To be considered, applicants will complete an online form and explain why they are interested in attending a course and how it will benefit them and their department. One student will be selected per quarter.

Urban/Industrial Rescue Essentials™ Course:

- This 50-hour course is the starting point for rescuers working on rope and in confined spaces. This hands-on training course is for rescuers who respond to emergencies ranging from the depths of a confined space to the heights of an elevated structure or industrial platform.

- Participants will be provided an opportunity to become proficient at utilizing some of the most current equipment in the rescue world while learning and practicing safe, efficient, and proven rescue techniques. These skills will allow them to perform effectively in the rigorous environments faced by urban and industrial rescuers.

- Courses will be conducted at the Roco Training Center (RTC), participants will practice rescue operations from all six (6) confined space types including rescues from elevated vessels and towers. Simulated rescues from IDLH-type atmospheres that require the use of breathing air (SCBA) will also be included. These realistic scenarios can be used to document annual practice requirements as required by OSHA 1910.146.

Roco Rescue hopes that this free training will help broaden the range of skills in confined space and rope rescue for firefighters and their departments.

Offer valid for USA-based emergency responders only based on space availability. Must be 18 years or older and physically fit to participate in hands-on rescue exercises. Offer is valid for limited time and subject to change without notice.

Additional Resources

So, you’ve got your rescue team up to date on all the nifty tricks in confined space rescue. Litters, knots, anchoring, mechanical advantage systems, the whole kit, and kaboodle. Now, you’ll need some first aid and CPR training to meet OSHA’s standards. Some folks say a simple layperson first aid course will do it. Others argue that teams need a week-long EMS professional course to prepare. Going further, some folks say that investing in drills and skills retention is the most critical issue. To cut through some confusion, let’s look at some of the things employers might factor in when choosing medical training for Emergency Response and Rescue Teams.

So, you’ve got your rescue team up to date on all the nifty tricks in confined space rescue. Litters, knots, anchoring, mechanical advantage systems, the whole kit, and kaboodle. Now, you’ll need some first aid and CPR training to meet OSHA’s standards. Some folks say a simple layperson first aid course will do it. Others argue that teams need a week-long EMS professional course to prepare. Going further, some folks say that investing in drills and skills retention is the most critical issue. To cut through some confusion, let’s look at some of the things employers might factor in when choosing medical training for Emergency Response and Rescue Teams. Now, let’s take a look at CPR or Cardiopulmonary Resuscitation. Simply put, rescuers will perform chest compressions to pump blood around the body and typically breathe for the patient. But wait, don’t I need to shock the patient? What about the AED (Automated External Defibrillator)? Am I required to have an AED in my first aid supplies? A

Now, let’s take a look at CPR or Cardiopulmonary Resuscitation. Simply put, rescuers will perform chest compressions to pump blood around the body and typically breathe for the patient. But wait, don’t I need to shock the patient? What about the AED (Automated External Defibrillator)? Am I required to have an AED in my first aid supplies? A

If you don’t use it, you lose it. Regardless of the course, the most critical component of any program is drilling and skills retention. In a

If you don’t use it, you lose it. Regardless of the course, the most critical component of any program is drilling and skills retention. In a

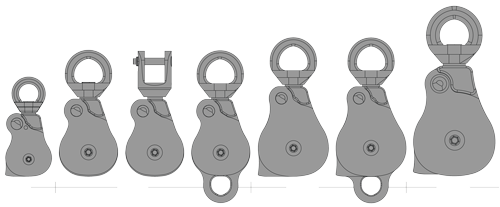

Inspect all CMC ProSwivel or Rock Exotica Omni-Block swivel pulleys immediately.

Inspect all CMC ProSwivel or Rock Exotica Omni-Block swivel pulleys immediately.

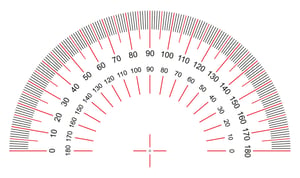

It is not just the degree of slope that tells me what I need to do, it is also the terrain and the condition of the terrain that makes a BIG difference. The terrain AND the slope are going to be major factors in deciding what rope systems to use as well as how many personnel are involved in the rescue. Some examples of terrain that may push you to utilize ropes in a rescue situation would include loose rock/scree, mud, snow, or any other debris that could cause bad footing and an unstable rescue for the patient. Ropes may have to be used to gain access to the victim, to support the team members and the patients during the rescue and remove them from the rescue site.

It is not just the degree of slope that tells me what I need to do, it is also the terrain and the condition of the terrain that makes a BIG difference. The terrain AND the slope are going to be major factors in deciding what rope systems to use as well as how many personnel are involved in the rescue. Some examples of terrain that may push you to utilize ropes in a rescue situation would include loose rock/scree, mud, snow, or any other debris that could cause bad footing and an unstable rescue for the patient. Ropes may have to be used to gain access to the victim, to support the team members and the patients during the rescue and remove them from the rescue site.