Does a competent person inspect your rescue equipment each year?

If not, you may want to consider having an independent third party perform the inspection for you. This service is offered by Roco as a stand-alone service, or it can be added to your next private training session.

Functional Ops Check

The service includes a “sight and touch” functional inspection of hardware, nylon products (including rope, webbing, and anchoring components), harnesses, and accessory equipment (including litters and stretchers) utilized in confined space/high angle applications. The inspection will be conducted in accordance with manufacturer’s specifications and will satisfy the requirement for an annual2 inspection by a competent person.Note: Equipment recommendations will NOT be provided by inspection personnel unless requested to do so.

Service Inspection Benefits include:

.jpg)

• Certified personnel to inspect equipment to manufacturer's standards.

• Inspection documentation from an independent third party.

• Frees your personnel from the responsibility of equipment inspections.

A full report of findings will be provided to include accessibility of equipment to responders and any other recommendations to improve overall team performance. It will include other pertinent information such as the manufacturer, product number, and serial/lot number (where applicable), date of manufacture, and in-service date (when available). It will also include the results of pass/fail testing for both visual and functional inspection. All equipment deemed unsuitable for use will be tagged for removal from service.

Regardless of the stated service life, the condition of equipment – as determined through inspection by a qualified party – is a key factor in determining whether or not a piece of equipment is fit for service.

Although the definition of “equipment lifespan” is very broad depending on the manufacturer, each provides specific instructions on proper inspection of equipment and detailed explanations on when to retire the service item. Several general identifiers that pertain to all equipment are shown below.

Reasons for Equipment Retirement include:

• Item fails to pass any pre/post use or competent person inspection.

• Item has been subjected to a major fall or load.

• Item is constructed of plastic or textile material and is older than 10 years.

• You cannot determine the complete full-use history of item.

• You are not certain or have lost confidence in the equipment.

A 10-year service life for nylon/polyester products is set according to ASTM F1740-96 (American Society for Testing and Materials).

Inspect Rescue Equipment Every Time It’s Used

All team members should be qualified and knowledgeable enough to perform pre- and post-use inspections of equipment. It is crucial that all members document each use of equipment, denote any deficiencies, and report to the proper person. One person should be designated to perform the competent person annual inspection. This person should have complete knowledge of the equipment and inspection procedures as well as the authority to keep or remove equipment from service as they see fit. If team members are unable to fill this role, a qualified third party with applicable manufacturer certifications in competent person inspection should be utilized to assist in determining the condition and estimated service life of rescue equipment.

Download Roco's Quick Checklist for your convenience. →Rescue team members are encouraged to attend this inspection where they will receive information on proper pre- and post-use inspections for their equipment. Guidance can be also offered in areas of equipment care, inspection, record-keeping, and proper storage. Again, equipment recommendations will not be addressed unless specifically asked to do so – this is only an inspection of the equipment you currently have on site.

Remember, with rescue gear, lives are literally “on the line,” – if in doubt, throw it out!

To schedule your Roco Competent Person Inspection, or add it to your current training dates, call us at 800-647-7626 or email info@rocorescue.com. Roco offers this service at no charge for current customers or for a very nominal fee for non-customers.1

1 Current customers receive a one-day equipment inspection at no charge. Travel expenses apply for out-of-town customers.

2 References include: 1926.502 Appendix C; ANSI Z359.2 Section 5.5.2 Inspections; ASTM Rope Inspection Guide; NFPA 1983 Section 5.2; ANSI Z359.11 Annex A (harnesses); and ANSI Z359.4 Section 6.1.

NOTICE: The client remains responsible for ensuring that all guidelines and requirements for maintaining and, where indicated, removal of equipment from service, are followed. This includes removing equipment from service anytime there is a situation or incident that occurs during handling, training, or rescue, that might have caused damage or otherwise compromised the integrity of the equipment, particularly where internal damage that is not visible might be present (e.g. equipment dropped from height, exposure of nylon products to chemicals or other potentially degrading substances, etc.). Client will be required to complete a certification that between Roco inspections, the equipment was properly stored, was available only to personnel trained to use the equipment properly, and that any equipment that was exposed to any condition or occurrence that could have resulted in hidden damage has been removed from service. A company representative, preferably someone from the rescue team, must be present during the inspection process.

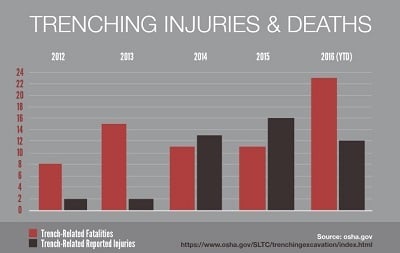

The new OSHA statistics show in 2016, we have two people a month dying in trenches, which is double the amounts for 2014 & 2015. Why, is the soil getting more dangerous? I can only speak to what I have seen in trends in industry that may be contributing to this rise. In previous articles, I have discussed the subject of trench and trench rescue and some of the following concerns:

The new OSHA statistics show in 2016, we have two people a month dying in trenches, which is double the amounts for 2014 & 2015. Why, is the soil getting more dangerous? I can only speak to what I have seen in trends in industry that may be contributing to this rise. In previous articles, I have discussed the subject of trench and trench rescue and some of the following concerns:

Oxygen-Depleted Atmospheric Hazards in Confined Spaces

Oxygen-Depleted Atmospheric Hazards in Confined Spaces My experiences in the altitude chamber were educational and potentially lifesaving if I were ever exposed to a low oxygen environment. By having experienced my subtle symptoms multiple times, perhaps I would recognize them in a lower than normal oxygen environment and be able to take action to rescue myself. However, the environment that I was exposed to was probably in the range of 12% oxygen by volume give or take. In lower concentrations, say below 10%, the onset of impaired judgment would be so rapid that I would have little chance to recognize and react on my own behalf. In extremely low concentrations of 0-8%, there is little chance for anyone to take self-rescue actions. More than likely, the individual will pass out after only one or two gasping breaths. And, most importantly, my experiences were in a controlled environment with highly trained observers and emergency personnel standing by. This is not always the case during confined space entry operations.

My experiences in the altitude chamber were educational and potentially lifesaving if I were ever exposed to a low oxygen environment. By having experienced my subtle symptoms multiple times, perhaps I would recognize them in a lower than normal oxygen environment and be able to take action to rescue myself. However, the environment that I was exposed to was probably in the range of 12% oxygen by volume give or take. In lower concentrations, say below 10%, the onset of impaired judgment would be so rapid that I would have little chance to recognize and react on my own behalf. In extremely low concentrations of 0-8%, there is little chance for anyone to take self-rescue actions. More than likely, the individual will pass out after only one or two gasping breaths. And, most importantly, my experiences were in a controlled environment with highly trained observers and emergency personnel standing by. This is not always the case during confined space entry operations.

From the basics of First Aid/CPR to Basic Life Support for Prehospital Providers, Roco now offers medical training from our professional instructors and experienced emergency responders. This training is designed to provide hands-on instruction for those requiring these lifesaving skills as part of their job – particularly those who work in industrial environments. Students will be taught the critical skills necessary to provide basic first aid for medical, environmental and traumatic injuries.

From the basics of First Aid/CPR to Basic Life Support for Prehospital Providers, Roco now offers medical training from our professional instructors and experienced emergency responders. This training is designed to provide hands-on instruction for those requiring these lifesaving skills as part of their job – particularly those who work in industrial environments. Students will be taught the critical skills necessary to provide basic first aid for medical, environmental and traumatic injuries.