The short answer…. of course, it is! Whether you are a large company or a small company (like ours), we have experienced that VPP can be a “win-win-win” for all who participate. The collaboration between employers, employees, and OSHA is one of the most refreshing aspects of VPP participation.

The short answer…. of course, it is! Whether you are a large company or a small company (like ours), we have experienced that VPP can be a “win-win-win” for all who participate. The collaboration between employers, employees, and OSHA is one of the most refreshing aspects of VPP participation.

By bringing those three groups together to determine any areas that can enhance worker safety, and do so with a team spirit, is not only effective but also goes a very long way in building a trusting rapport.

It’s important to note that OSHA VPP is a voluntary program, and that is the first hint that the entire process is based on a triad of cooperation and support. Therefore, with the VPP process, the first thing you need to remember is that OSHA is here to help you. No, really…in our VPP experience, there has been one example after another of OSHA representatives being very helpful and supportive throughout the process. Ultimately, this has created a safer workplace and enhanced the safety culture of our company. More on that in a bit.

No doubt, there’s a lot of upfront effort in preparing for your first onsite VPP audit. OSHA realizes that the initial onsite audit and the self-evaluation package are not easy or quick “blink-of-the-eye” efforts. However, OSHA makes it less daunting by helping to arrange for a “mentor VPP company” to assist new applicant companies. These VPP volunteers act as mentors throughout the preparation process.

For starters, any company seeking entry into the VPP program must have a very safe OSHA-compliant workplace with all the programs expected of VPP in place. The applicant must be able to demonstrate compliance with the four main VPP Elements and all the sub-elements, which are quite extensive. In addition, continuous safety improvement is a never-ending focus with VPP.

To address all VPP elements and sub-elements takes a fair amount of effort and understanding of how best to put into words a narrative description of your safety and health programs. Then, you must be able to tie it to the documentation that backs it up. There is a high potential for a shortfall or disconnect between what OSHA is looking for and what you think they are looking for, and that happened to us on our first audit. It wasn’t a major factor, but it was enough to cause the audit team to call a time out on the process and give us some appropriate guidance and time to revise that particular sub-element to meet the requirements of the program. It was more a matter of semantics than execution, but the point is, the OSHA team cooperated with, and supported us. Ultimately, we were awarded our VPP Star status at the conclusion of that audit.

Earlier I referred to a triad of cooperation and support, but all I have mentioned so far is OSHA and the employer. So, who makes up the third point of the triad? That would be the employees. The four elements of VPP are very clear – not only is management leadership a very big part of the program, but as importantly, so is employee involvement – the third point of the triad!

We’ve found that one of the greatest benefits of participating in the VPP program is how it gets all the employees involved. For a safety culture to evolve in a workplace, it is an absolute must that the employees have a stake in their own safety and the safety of others around them. To have any feeling of ownership, or having a stake in the success of the program, employees must not only feel that their input matters, but the program must include employee input not just as a mindset, but that it is demonstrable through documentation.

One of the most beneficial outcomes of employee involvement is the development of programs that don’t just sound good on paper, but actually work in application.

By asking employees for their ideas on how best to make their area not only meet the requirements of the program, but to make it a usable, and most importantly an effective tool or strategy – and who better to hear this from than the person(s) that will be implementing the tool? By allowing the employees to come up with solutions for providing for their own safety in concert with management support and leadership, we are finding that the safety culture, as well as the overall safety of the workplace, has been greatly enhanced.

So how does participation in the VPP program help you as a company? Out of all the programs, growth, changes, new classes, equipment, facility additions and other significant events that I have witnessed over the past 20+ years with Roco Rescue, the teamwork and communication between employees and management was never as dynamic as it has been due to our participation in VPP.

Roco has always placed safety first and our motto, “There’s a Safe Way, and a Safer Way!” has always rung true in our day-to-day business. But even with such a strong record of safety before VPP, it is clear that our workplace safety has gotten much stronger and that is due primarily to our work with OSHA VPP. The program has provided the tool for our management team; and, most importantly, our employees to develop new and safer practices and programs.

I mentioned VPP being a win-win-win situation earlier. I think it is clear how the employer and employees benefit from participation in VPP, but one of the benefits to OSHA is witnessing innovative safety practices and how those practices result in measurable safety benefits. To illustrate this, I want to share a story from one of the onsite VPP evaluations I assisted with as an SGE.

During the visit, the OSHA evaluation team learned of a monitoring program for companies that use forklifts and lift trucks as part of their daily activities. This monitoring system consisted of hardware and software that monitors vehicle speed, any impacts in a selectable value or G force, maintenance and inspection status, and other criteria. The company had seen a 90% reduction in the costs associated with forklift and lift truck maintenance and materiel damage associated with these types of operations. This reduction does not include any costs that would be a result of injury or fatality. The overall reduction in over-speed and impact incidents should directly correlate with any injury or fatality potential. This is an example of an OSHA benefit in collecting best-known practices (BKM) and sharing that BKM with other companies.

Now all this being said, it is by no means a given that simply applying for OSHA VPP participation and undergoing an onsite evaluation will result in your company receiving recognition in any of the three VPP programs – Star, Merit, or Demonstration. But remember, VPP is a cooperative effort, and this means that any shortfalls in your safety program or performance will be clearly identified.

Written evaluation reports will be given that provide a great roadmap to help you not only make corrections to achieve VPP recognition, but most importantly to provide a safer, healthier, and ultimately a more profitable workplace.

So, is the OSHA VPP program a good fit for your company? From our experience, we feel very strongly that it is a good fit for any company. In addition, there are many more benefits to participation in VPP than what we covered in this article including preferred consideration by clients who also value a safety focus. However, for Roco, the most important has been the enhanced safety throughout our operations and the companywide buy-in from our employees and support from management.

HERE'S MORE...

What is VPP?

The OSHA Voluntary Protection Program (VPP) promotes effective worksite-based safety and health. In the VPP, management, labor, and OSHA establish cooperative relationships at workplaces that have implemented a comprehensive safety and health management system. Approval into VPP is OSHA’s official recognition of the outstanding efforts of employers and employees who have achieved exemplary occupational safety and health.

How Has VPP Improved Worker Safety & Health?

Statistical evidence for VPP’s success is impressive. The average VPP worksite has a Days Away Restricted or Transferred (DART) case rate of 52% below the average for its industry. These sites typically do not start out with such low rates. Reductions in injuries and illnesses begin when the site commits to the VPP approach to safety and health management and the challenging VPP application process.

How Does VPP Benefit Employers?

Fewer injuries and illnesses mean greater profits as workers’ compensation premiums and other costs plummet. Entire industries benefit as VPP sites evolve into models of excellence and influence practices industry-wide.

How Can I Get More Information?

For more information, visit https://www.osha.gov/vpp or download Roco's Continuous Safety Improvement Cycle poster with details about each of the four elements of VPP.

About the Author: Pat Furr has recently retired from Roco and is currently “living the dream” in New Hampshire. He was a chief instructor, technical consultant, VPP Coordinator, and Corporate Safety Officer for Roco for many years. As a chief instructor, he taught a wide variety of technical rescue classes including Fall Protection, Rope Access, Tower Work/Rescue and Suspended Worker Rescue. In his role as technical consultant, he was involved in research and development, writing articles, and presenting at national conferences. Prior to joining Roco in 2000, Pat served 20 years in the US Air Force as a Pararescueman (PJ).

will be a fixture in a rope rescuer’s toolkit. These are critical components of a two-tension system because they provide the three primary functions two-tensioned systems require – friction control, belay, and haul. By providing two mirrored tensioned systems during a lower, the forces on either of the systems are essentially cut in half. This greatly reduces stress on the system and is more easily managed by the operator working with heavier rescue loads.

will be a fixture in a rope rescuer’s toolkit. These are critical components of a two-tension system because they provide the three primary functions two-tensioned systems require – friction control, belay, and haul. By providing two mirrored tensioned systems during a lower, the forces on either of the systems are essentially cut in half. This greatly reduces stress on the system and is more easily managed by the operator working with heavier rescue loads.  Also, as mentioned previously, using a mirrored 3:1 or 5:1 Z-rig through a Maestro or other similar device during hauling operations will double the mechanical advantage compared to using a single haul system. Applying two 3:1 mirrored MAs results in a 6:1 total MA. This can reduce the manpower required for the haul team, which is beneficial for a variety of reasons.

Also, as mentioned previously, using a mirrored 3:1 or 5:1 Z-rig through a Maestro or other similar device during hauling operations will double the mechanical advantage compared to using a single haul system. Applying two 3:1 mirrored MAs results in a 6:1 total MA. This can reduce the manpower required for the haul team, which is beneficial for a variety of reasons. in late January 2020. We’ve been testing it out for a few months and wanted to share our findings. We think our readers will find this particularly relevant since the Maestro is designed specifically for technical rescue.

in late January 2020. We’ve been testing it out for a few months and wanted to share our findings. We think our readers will find this particularly relevant since the Maestro is designed specifically for technical rescue.

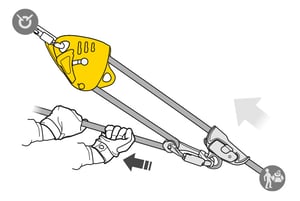

The Maestro transitions from lowering to hauling very nicely. We like that it gives the user an auditory cue – it clicks in haul mode as the uni-directional pulley sheave moves with the rope. It’s easy to set up a 3:1 z-rig using a pulley and a rope grab like the Petzl Rescucender. This is where the Maestro really shines, thanks to the efficiency characteristics of its design. Its large-diameter sheave coupled with sealed ball bearings only allow the pulley to rotate in one direction, creating a progress-capture system that minimizes loss of haul-gains. As the user hauls the load, the Maestro’s auto-lock feature locks in the progress made, and the user can then extend the rope grab back out and continue hauling.

The Maestro transitions from lowering to hauling very nicely. We like that it gives the user an auditory cue – it clicks in haul mode as the uni-directional pulley sheave moves with the rope. It’s easy to set up a 3:1 z-rig using a pulley and a rope grab like the Petzl Rescucender. This is where the Maestro really shines, thanks to the efficiency characteristics of its design. Its large-diameter sheave coupled with sealed ball bearings only allow the pulley to rotate in one direction, creating a progress-capture system that minimizes loss of haul-gains. As the user hauls the load, the Maestro’s auto-lock feature locks in the progress made, and the user can then extend the rope grab back out and continue hauling.

OSHA 1910.146 Appendix F

OSHA 1910.146 Appendix F