The following article was featured in the July 2014 issue of ISHN, and authored by Roco's own Chief Instructor Pat Furr.

The following article was featured in the July 2014 issue of ISHN, and authored by Roco's own Chief Instructor Pat Furr.

Have you ever wondered who that person is who hovers around the portal of a permit space while workers are in the space? What does a Confined Space Attendant (often referred to as the “Hole Watch”) do anyway? What may seem like a cushy job is actually a critical safety responsibility. Here’s why:

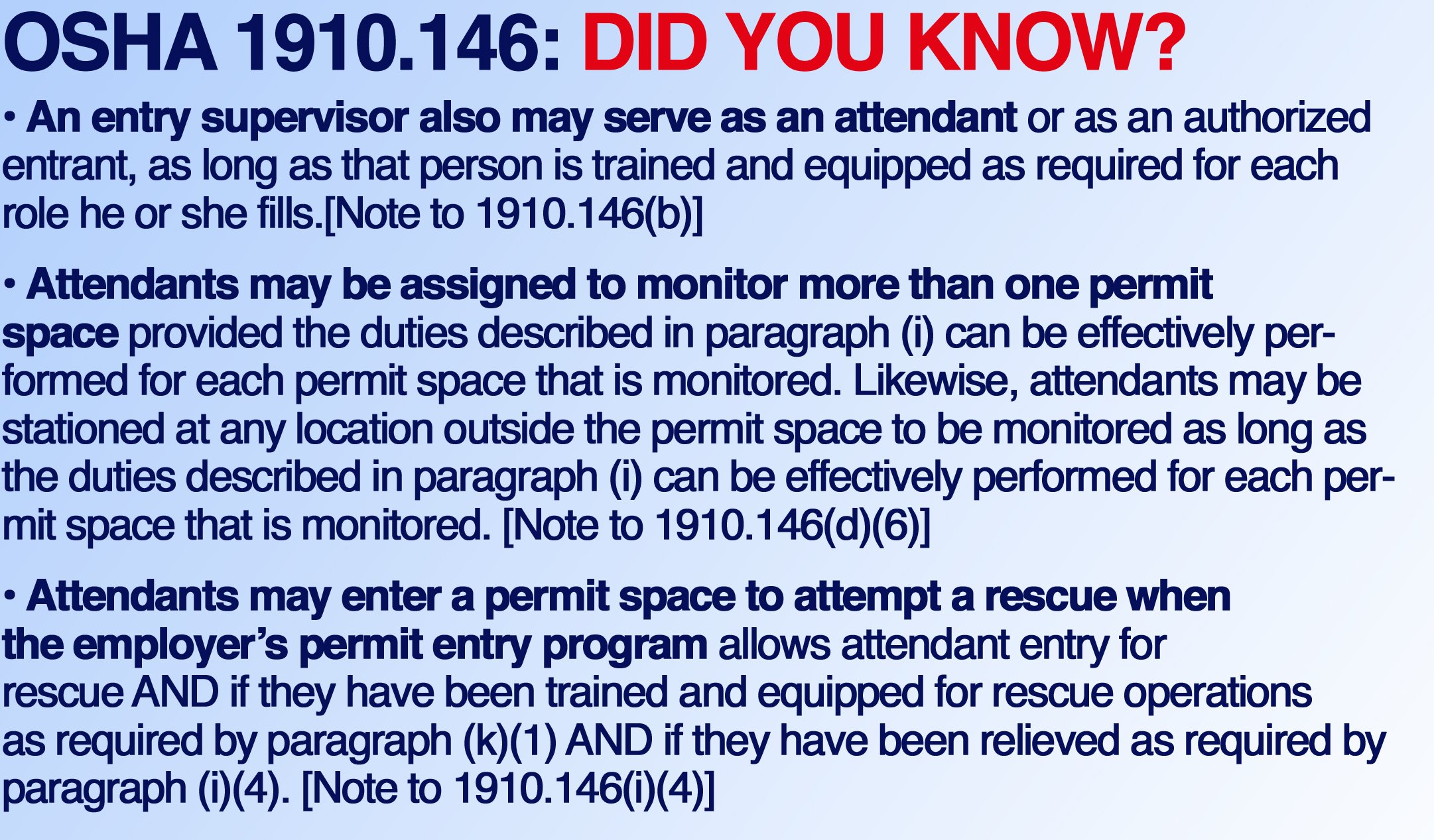

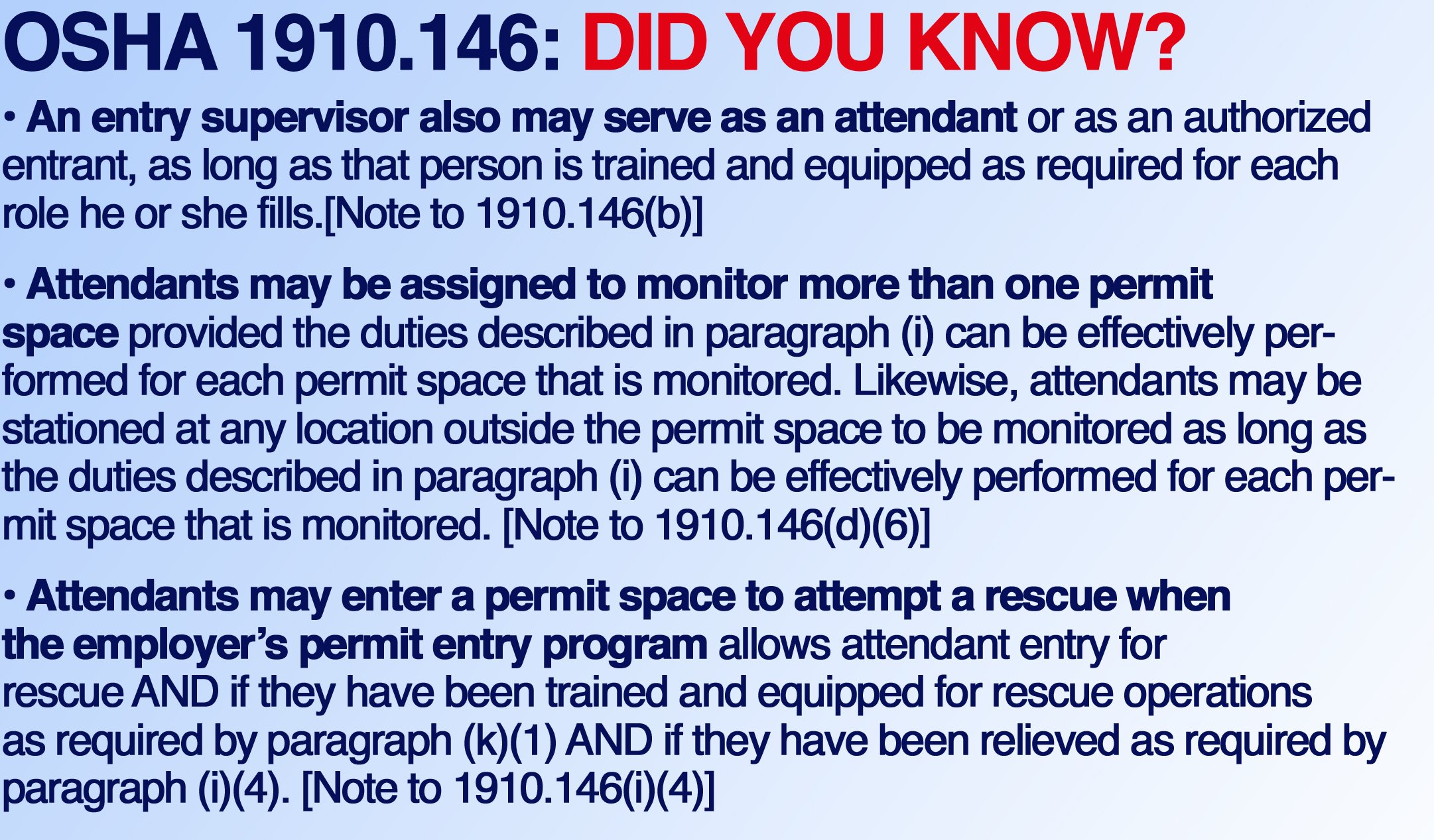

First, OSHA instituted regulations regarding Permit-Required Confined Spaces (1910.146) due to the high number of serious injuries and deaths in confined spaces. Entering these spaces is dangerous business, and the attendant serves as the “safety watchman” for entrants as well as those who may casually try to enter. This also applies in an emergency situation when others may be tempted (but unqualified) to enter the space to rescue a co-worker.

OSHA requires that the attendant be able to safely and effectively perform the duties required in Section (i) of 1910.146. (See “Duties of the Confined Space Attendant”) Once a permit is issued and work begins, the attendant needs to be aware of his or her surroundings and be diligent in monitoring the space and entrants at all times. This individual is not there to be a “gofer” for workers inside the space.

Get real

Get real

If entrants need assistance or an emergency situation develops inside (or outside) the space that requires entrants to be evacuated, the attendant is the “vital link”. Unfortunately, it is common practice to fill the Hole Watch position with the least experienced or greenest person on the crew. Many times, this person has no idea what is expected of them. They also may not be aware of potential hazards inside the space or hazards that may be introduced as work is performed. Often, these individuals are not experienced in industrial environments and are not properly trained in the OSHA-required duties. And, in most cases, they don’t realize how critical their duties could become in an emergency when split-second decisions are required.

Train your attendants

It is unrealistic to expect a new employee to perform these duties without receiving appropriate training and being granted the authority to take action as needed. In 1910.146(d)(8), OSHA is specific in its requirements for the various roles involved in conducting safe permit entry operations. Employers are required to provide adequate training and ensure that personnel are capable of performing their duties. At minimum, the regulation requires employers to ensure that each Hole Watch/Attendant knows and understands the following safety precautions:

(1) Hazards that may be faced during entry, including information on the mode, signs or symptoms, and consequences of exposure to those hazards;

(2) Possible behavioral effects of hazard exposure for the authorized entrants.

Additional duties and responsibilities include:

(1) Continuously maintaining an accurate count of entrants in the permit space.

(2) Performing non-entry rescues as specified by the employer’s rescue procedure.

One of the most critical duties of the attendant is to be able to effectively communicate with entrants and take appropriate actions in an emergency. Communications are required to monitor the status of the entrants and to ensure that there are no signs of exposure to hazards. The attendant must recognize this need and be able to order evacuation of the space. Most importantly, the confined space attendant can perform NO duties that might interfere with their primary duty to monitor and protect the entrants.

Prevent fatalities

Employers must ask themselves, “Will the person designated as the “Hole Watch” be able to react in an effective manner when the pressure is on? Will they be able to initiate a non-entry rescue in an emergency situation?” Again, we witness too many instances where the “Hole Watch” has little or no knowledge of the responsibilities assigned, while some have had virtually no training whatsoever. Sometimes it seems they are there for no other reason than to fill a square to meet an OSHA requirement.

Many times the lack of understanding regarding confined space hazards, combined with the lack of a clear understanding of emergency actions to be taken (as well as actions to avoid) can lead to confined space fatalities, both for the entrants as well as the attendant.

We urge employers to take a serious look at the selection and training of confined space attendants. These individuals must be capable, responsible and properly trained as spelled out in the OSHA standard. When things go wrong in a confined space, the actions (or inaction) of the attendant can be the difference between life and death for the entrants. They must have the knowledge, the tools and the experience to function as an effective, and ultimately safe, “Hole Watch.”

Additional Resources

- Attendant Safety Requirements Poster (pictured here)

- Confined Space Entry Checklist

- Common Causes of Confined Space Fatalities

- Limitations of Atmospheric Monitors

Get real

Get real Recently, we noticed a story in a leading safety and health magazine that questions the “two-piece, pass-through buckle” that is commonly used on many harnesses. The author, in fact, referred to it as a design flaw. However, we consider it more a matter of improper use than a design flaw. While he does identify some potential user failures, we feel his terming is not quite accurate. Here’s why...

Recently, we noticed a story in a leading safety and health magazine that questions the “two-piece, pass-through buckle” that is commonly used on many harnesses. The author, in fact, referred to it as a design flaw. However, we consider it more a matter of improper use than a design flaw. While he does identify some potential user failures, we feel his terming is not quite accurate. Here’s why...

Prompted by the

Prompted by the