By Skip Williams

Contributors: Deputy Chief Kenneth Jenkins, Captain Tom Horn and Captain Anthony Morley, Charleston Fire Department, Rescue 115, and Russ Fennema, Jay Dee Contractors

Note: The following article recounts a very successful rescue that took advantage of available resources at the scene. Roco Rescue wants to share stories like this one to remind our readers that lessons learned can be gleaned from successful rescues just as they can from rescues that didn’t go so well. The important point is to take the time to perform a debriefing as soon as possible after the rescue effort. This is the time to capture the thoughts and comments from the team members while it is still fresh in their memories. Any important lessons learned need to be captured through documentation and then SHARED. The learnings can become part of your SOP/SOI or they can become integrated into your formal training.

The other point that this article makes is to know and understand your equipment. We regularly train with our ropes and hardware, and we all tend to learn the operating limits and capabilities of said equipment. However, we need to be just as familiar with our peripheral equipment such as atmospheric monitors, radios, and etcetera. Consider spending some of your team training time learning more about that equipment and how to properly use it and what its idiosyncrasies may be. All the equipment we use should be considered life support equipment, and the word “life” should grab your attention and motivate you to know all you can about it.

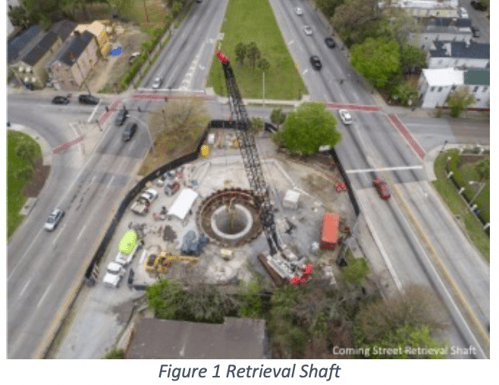

In March 2019, Rescue 115 of the Charleston Fire Department was dispatched at 09:02 hours to “man down” at an address on Shepard Street some 5 1/2 blocks NW of station 15 on Coming Street. En route, Captain Tom Horn realized the address was familiar as the entrance to the Coming Street retrieval shaft of the Charleston tunnel project (Figure 1). Now they were 2 blocks from the scene and he immediately called for Ladder 4 also from station 15, and nearby Engine 6 and Battalion 3 from nearby station 6. R115 arrived at 09:06 hours.

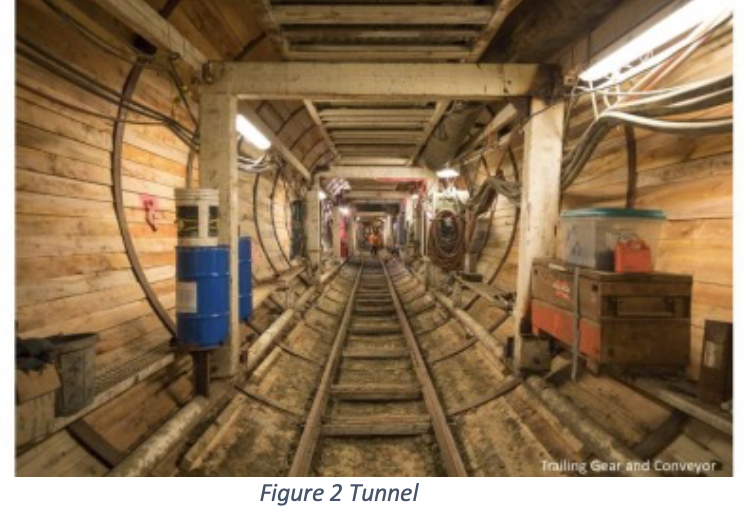

The Coming Street retrieval shaft is a vertical shaft 168 feet down and 20 feet in diameter to a 15-foot diameter tunnel being bored for flood control (Figure 2). Just as R115 arrived at the scene, the 12-man cage had been weight tested and prepared for lowering by crane. As R115’s four-man crew was about to be lowered into the shaft, Captain Horn eyed Captain of Ladder 4 and transferred command to him.

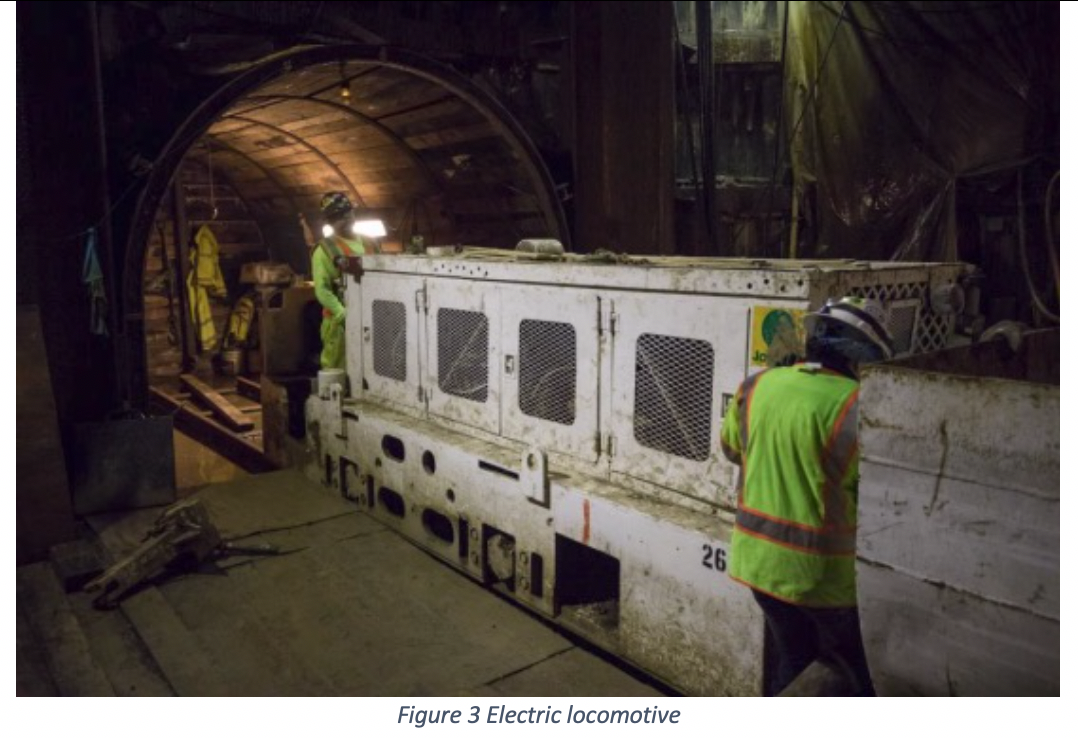

Just as R115’s crew got to the bottom, the patient arrived at their location from three quarters of a mile in the tunnel on a horizontal flat car driven by a battery-powered locomotive (Figure 3).

Captain Horn called for the lowering of the backboard and Stokes basket. The topside crew decided to use the crane again rather than lower with ropes. The county EMS was not included as joint training is not done. Back down at the tunnel, the patient was secured, placed in the 12-man cage, along with R115 members and 2 construction workers. The patient at the top of the shaft was treated by county EMS and was off to the hospital at 09:40 just 38 minutes from the initial call.

There are always lessons learned at any rescue. From prior experience, a member was assigned to the crane operator to ensure that the crane was moved under Fire Department control. The Fire Department used the construction company’s gas detectors because they knew that the detectors were calibrated daily. In retrospect, the Fire Department would use its own gas detectors. Also, the backboard and Stokes basket should have gone down on the first lowering to the tunnel.

The usage of gas monitors had been delayed because of differences in calibration between the fire department monitor and a plant monitor. There is no one gas that is best for calibration of fire department gas detectors because many different exposures are encountered. For a particular industrial site, the explosive gases are most likely known.

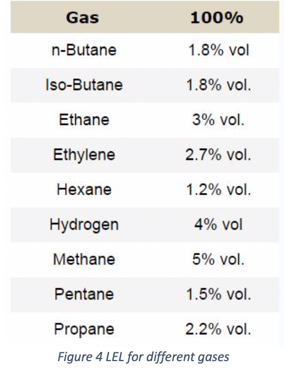

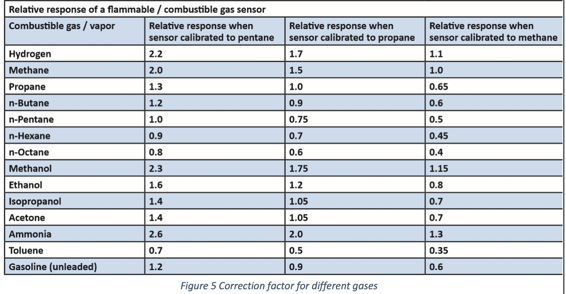

Figure 4 shows that the Lower Explosive Limit (LEL) varies according to which hydrocarbon is present. Figure 5 shows correction factors if the monitor is calibrated with one gas and exposed to another. The Fire Department meter was calibrated with methane so that 0.5% by volume of methane reads 10% of LEL. A meter calibrated with pentane has a correction factor of 2 for methane. So, if a meter calibrated with pentane reads 10% LEL in pentane, the meter would read 5% LEL in methane. lf anything, the gas in the tunnel would be methane, but in actuality, the meters read zero no matter what calibration gas was used.

The reason pentane is sometimes used for calibration is that it overestimates the actual LEL. The caveat is that if the meter is poisoned for methane, a methane bump test is indicated. A sensor can be poisoned by chemicals like silicone. Note well, silicone is a component of Armor All which should not be exposed to a LEL meter on a fire truck. The lesson learned here is to understand the effect of different gases on a sensor and a Fire Department may encounter many different gases.

The reason pentane is sometimes used for calibration is that it overestimates the actual LEL. The caveat is that if the meter is poisoned for methane, a methane bump test is indicated. A sensor can be poisoned by chemicals like silicone. Note well, silicone is a component of Armor All which should not be exposed to a LEL meter on a fire truck. The lesson learned here is to understand the effect of different gases on a sensor and a Fire Department may encounter many different gases.

Author Bio:

Skip Williams was a volunteer firefighter for 20 years. His last position was captain of the high-angle rescue team and emergency medical technician. He has a Bachelor of Electrical Engineering from Georgia Tech and M.S. and Ph.D. from Rutgers University and has held teaching positions at Rutgers University and the Medical College of Georgia. He designed and patented an artificial heart assist device. He is a Registered Professional Engineer in New Jersey and is a practicing engineer with Condition Analyzing Corporation engaged in condition monitoring of ships.

Note: Captain Tom Horn is a graduate of two Roco Rescue courses.

My initial idea for this interview was to discuss how a piece of rescue equipment goes from idea to design and manufacturing, and finally into our gear bags. However, a funny thing happened during the course of this chat. I realized that this story is about so much more than designing and manufacturing equipment.

My initial idea for this interview was to discuss how a piece of rescue equipment goes from idea to design and manufacturing, and finally into our gear bags. However, a funny thing happened during the course of this chat. I realized that this story is about so much more than designing and manufacturing equipment.  It was after the

It was after the  make the best carabiners in the world, and I knew that the key lock design was really good, so we licensed that design for our gate interface. Of course, it is more difficult to make a carabiner that has that interface opposed to more traditional claw or pin latch gates, but once we bought a CNC machining center, we were able to produce them much more efficiently with very high quality for the tolerances required. I made a feeder that would feed the blanks in automatically and clamp the blank. We were able to optimize the strength with the exact clearances so the gate wouldn’t drag on the frame and all kinds of technical things so we ended up with the performance and strength we wanted. We made everything in-house - the frame, the gates, and the sleeves - so we were able to get everything right so that it synchronizes correctly and the sleeve closes when you want it to but not before. This would have been impossible to do if we outsourced the various components from other sources. Because we made everything ourselves, I could change something by 5/1000 of an inch on the fly to really fine-tune it.

make the best carabiners in the world, and I knew that the key lock design was really good, so we licensed that design for our gate interface. Of course, it is more difficult to make a carabiner that has that interface opposed to more traditional claw or pin latch gates, but once we bought a CNC machining center, we were able to produce them much more efficiently with very high quality for the tolerances required. I made a feeder that would feed the blanks in automatically and clamp the blank. We were able to optimize the strength with the exact clearances so the gate wouldn’t drag on the frame and all kinds of technical things so we ended up with the performance and strength we wanted. We made everything in-house - the frame, the gates, and the sleeves - so we were able to get everything right so that it synchronizes correctly and the sleeve closes when you want it to but not before. This would have been impossible to do if we outsourced the various components from other sources. Because we made everything ourselves, I could change something by 5/1000 of an inch on the fly to really fine-tune it.  RT: Fantastically! I appreciated the things I learned working with

RT: Fantastically! I appreciated the things I learned working with

swivels with pulleys but I thought it would be nice to save that extra length of a carabiner to connect the pulley to the swivel. It was a really fun design because you had to forget about normal pulley design. I became obsessed with designing it and would wake up in the middle of the night with an idea for it. It required that we machine a body that housed the axle, and the button to release the side plate, and a nice thick section to attach the swivel to. It was really fun to design and was perfect for our new 4-axis machines. It became a terrific success and that generated different sizes of the pulley. We now have one with a four-inch sheave, which has over a 30,000-pound breaking strength and is used a lot in material handling. I’m really proud of that product because it is totally different and it has revolutionized the way people are using pulleys.

swivels with pulleys but I thought it would be nice to save that extra length of a carabiner to connect the pulley to the swivel. It was a really fun design because you had to forget about normal pulley design. I became obsessed with designing it and would wake up in the middle of the night with an idea for it. It required that we machine a body that housed the axle, and the button to release the side plate, and a nice thick section to attach the swivel to. It was really fun to design and was perfect for our new 4-axis machines. It became a terrific success and that generated different sizes of the pulley. We now have one with a four-inch sheave, which has over a 30,000-pound breaking strength and is used a lot in material handling. I’m really proud of that product because it is totally different and it has revolutionized the way people are using pulleys.  RT: That’s a great question. I would never say that innovation is at

RT: That’s a great question. I would never say that innovation is at  PF: I know we will always have young students that are very strong in math and the sciences, but I feel there is still a huge need to get out and learn about levers, ramps and other tools and such in the physical world.

PF: I know we will always have young students that are very strong in math and the sciences, but I feel there is still a huge need to get out and learn about levers, ramps and other tools and such in the physical world.