![]() QUESTION FROM OUR READER:

QUESTION FROM OUR READER:

In the new Stokes lashing video the instructor tied 2 butterfly knots into the webbing. Can this also be done with 2 figure eight knots in the webbing? Also I was looking for the information on Sked lashing, with by-passing the top 2 grommets and starting with the first 2 on the sides.

ANSWER:

Roco Rescue

Recent Posts

Q&A: Tech Panel Answers

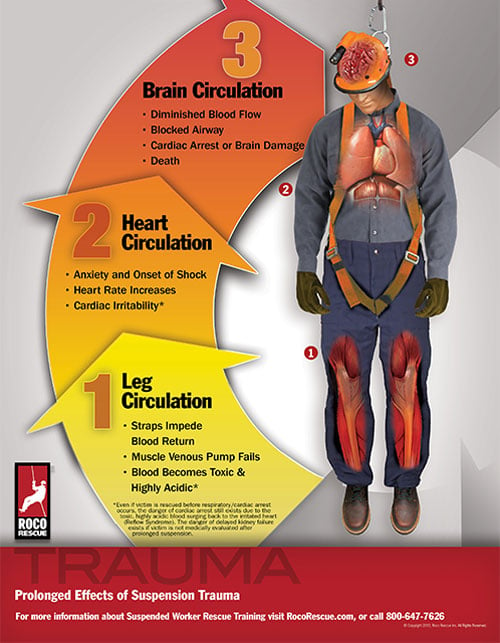

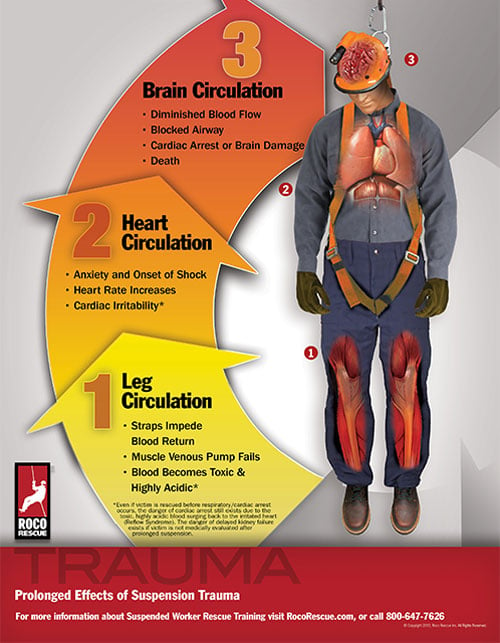

Suspension Trauma Explained: Safety Poster from Roco

What exactly is suspension trauma? How does it occur? And what can be done to prevent it?

What exactly is suspension trauma? How does it occur? And what can be done to prevent it?

Suspension Trauma - otherwise known as harness pathology, distributive shock, or orthostatic intolerance - has recently been identified by OSHA as a workplace hazard particular to Authorized Workers using personal fall arrest systems (PFAS). More and more employers are becoming aware of this workplace hazard and are taking appropriate steps to protect their employees. The range of understanding on the cause of the hazard, as well as how to protect against it, is pretty vast.

Our new Suspension Trauma Safety Poster is a tool to raise awareness of this hazard. It illustrates the pathological path that a fallen suspended worker may experience. Please share with colleagues, fellow safety professionals and especially workers that use PFAS. It could save a life.

The rate at which suspension trauma develops varies from individual to individual and is not reliably predictable. However, there are factors that influence the potential for suspension trauma as well as the speed of onset. Here are a few examples:

- Underlying physical condition of worker including any pre-existing respiratory or cardiac conditions;

- Worker’s ability to handle stress and anxiety;

- Harness selection, fit, and adjustment;

- Traumatic injuries that may have occurred during or before the fall; and,

- Knowledge and the use of equipment or techniques to delay the onset of suspension trauma such as temporary leg stirrups or simply “bicycling the legs.”

Roco also offers a course called Rescue From Fall Protection to educate rescuers who respond to suspended workers.

Pathological Effects of a Fallen Worker in Danger of Suspension Trauma

For those of you who prefer a more detailed explanation, here's the narrative from Roco Chief Pat Furr.

1. Leg Circulation: A fall arrest harness does a great job of dissipating the energies generated during a fall arrest through the long axis of the human body. After all motion has stopped, that same harness – particularly the dorsal attachment configuration – will most likely impose pressure to the femoral vein, which is the primary blood vessel that returns blood from the legs towards the heart. In fact, in order to pass certification testing, these harnesses must not allow the test mannequin to assume greater than a 30 degree forward lean upon suspension. Any degree of forward lean will exert leg strap pressure on the femoral vein which impedes blood return. To compound this, the human body relies on what is known as the muscle/venous pump to assist the blood return from the legs to the heart. In suspension, the worker often forgets to bicycle their legs to create this muscle/venous pump. The trapped blood in the legs creates what is known as distributive shock as more and more blood is trapped in the legs; there is less to circulate for the rest of the body (brain, heart, lungs, and kidneys). Additionally, this blood becomes highly acidic and toxic with metabolic wastes.

2. Heart Circulation: As the body goes into distributive shock, the heart must increase the rate and strength of its contractions to compensate. To compound this, the suspended worker may be experiencing a high degree of fear and anxiety, which releases adrenalin into the bloodstream which also causes the heart to work harder and faster. This places increased demands on the heart, which is receiving less blood flow and thus less oxygen. The heart becomes irritable and is prone to localized tissue damage, dysrhythmias or both. This is especially a concern once the worker is rescued and the toxic blood is allowed to surge from the legs to the irritable heart. This is known as reflow syndrome and has caused several victims to go into sudden cardiac arrest upon rescue.

2. Heart Circulation: As the body goes into distributive shock, the heart must increase the rate and strength of its contractions to compensate. To compound this, the suspended worker may be experiencing a high degree of fear and anxiety, which releases adrenalin into the bloodstream which also causes the heart to work harder and faster. This places increased demands on the heart, which is receiving less blood flow and thus less oxygen. The heart becomes irritable and is prone to localized tissue damage, dysrhythmias or both. This is especially a concern once the worker is rescued and the toxic blood is allowed to surge from the legs to the irritable heart. This is known as reflow syndrome and has caused several victims to go into sudden cardiac arrest upon rescue.3. Brain Circulation: As the victim goes into distributive shock, or worst case, suffers cardiac arrest, the brain is deprived of adequate blood supply and this can lead to unconsciousness. If the victim faints the airway can be blocked by the head position or even by a poorly adjusted harness that allows the chest strap to block the airway. That is a difficult statement to write into a fatality report “Cause of Death: Strangulation by Victim’s Own PPE.” If the victim’s heart stops, we can expect permanent brain damage or death in as little as four minutes.

So it should be obvious that a prompt rescue capability must be ensured by any employer that has Authorized Persons using PFAS. This can be accomplished in many ways. Roco has a variety of training courses that are specifically designed to provide that prompt rescue capability for fallen/suspended workers.

We also worked with CMC to design a new harness to protect suspended workers from suspension trauma.

For more information please contact Roco Rescue at 800-647-7626 or submit a question to our Tech Panel.

Roco Rescue Accepts Distinguished OSHA VPP Star Award

Roco Rescue was officially awarded the OSHA VPP Star at a ceremony on April 15th, making them the first rescue training, equipment and safety services company in the United States to receive the award.

Roco Rescue was officially awarded the OSHA VPP Star at a ceremony on April 15th, making them the first rescue training, equipment and safety services company in the United States to receive the award.

OSHA recognized Roco for their excellent safety history, practices and programs, which makes them a part of a distinguished community of approximately 2,400 other elite organizations in the nation who have met the rigorous guidelines for achieving VPP Star recognition.

Supporters gathered at the Roco Training Center in Baton Rouge to celebrate the rare designation. Senior VP/COO John Voinché introduced special guests and thanked them for their long-time support of Roco Rescue. An official OSHA plaque of honor was presented to Kay Goodwyn, President/CEO, before a VPP Star Worksite flag was raised at RTC by Chief Carroll Campbell and Denver Payne.

The Voluntary Protection Program (VPP) is based on a cooperative relationship between management, labor and government. VPP promotes worker protection, which requires active employee involvement and management commitment, while emphasizing the continual identification and elimination of hazards beyond OSHA standards.

“It's a commitment our people make at every level. Being in the business of safety and rescue services, it is essential that every Roco team member engage in the utmost safety at all times,” Kay Goodwyn said.

“It takes a conscious effort on everyone’s part, and we are extremely honored to be a part of this elite group.”

Above: The VPP Star Worksite flag is raised for the first time.

Right: Goodwyn accepts OSHA plaque from Roderic Chube, VPP Coordinator of the Baton Rouge Area OSHA Office.

Trench Training: A Careful Balance Between Realism and Safety

by Dennis O' Connell, Director of Training/Chief Instructor

This IPhone video captured at a recent training exercise is being posted here solely to illustrate the powerful nature of a trench collapse. Instructors were aware that a collapse was imminent and a “safe zone” was established along with other measures that will be discussed in this article. It’s important to note that all students were cleared from the area prior to releasing the struts for the collapse. This video is presented with the intention of helping trainers and rescuers achieve greater safety awareness during training events.

You’ve probably heard the saying “train as you play, and play as you train” many times. However, for rescuers, this training mentality is essential! Rescuers should have the ability to handle a wide variety of events, but must also appreciate the dangers of the job.

This behavior needs to be practiced but must also be balanced with safety as the #1 priority. To avoid injuries, a risk analysis must be conducted and carefully reviewed. This will help in planning the training exercises and in determining possible hazards where students may be most at risk. Everyone involved in the training exercises (including observers) should be informed of the dangers as well as control measures and safety requirements. Everyone should be aware that they have the ability to stop an evolution immediately should a safety concern be detected.

In order for this to happen, an established rescue plan should be devised for each element of training. An example in high angle training would be an “instructor’s line.” A designated instructor/rescuer, an additional line, and equipment should be staged and ready for a rescue, just in case. Teaching stations should also be set up in close proximity to allow for the use of the equipment from one station to another.

In our quest for realism, we need to constantly re-evaluate as the training proceeds. Risk vs. reward…is this training exercise worth the risk?

Now, let’s take a look at some common techniques used to increase pressure for rescuers and evaluate performance during a “simulated” rescue. Time limits are often used to increase stress levels while performing skills. In rope rescue training, knot tying and patient packaging are good examples where time restraints are a useful tool. On the other hand, if you set time restraints or implement a “speed reward” for how fast you can rappel down a building or perform a rescue, it can lead to unsafe actions that can cause injury or even death.

Here’s a deadly example of speed rewards during training. There was a video of tree trimmers taking their final exam. In the video, they were required to climb a ladder into a tree, anchor themselves off and hook up to a rappel line, rappel down to a simulated victim, and then lower themselves to the ground. In the video, the student is being timed, while being offered a reward for speed. In the process of doing so, the student missed a connection, as did the instructor, and fell to his death.

Another interesting means of rescuer stress or pressure that can develop unexpectedly during training is “peer pressure.”

In the same tape, students can be heard encouraging, for lack of a better word, individuals to beat the clock. If used in the correct manner, this friendly competition can be useful, but if not exercised properly, it can be dangerous. Competitive training exercises should be used only within the design of the class. If it develops unexpectedly, it should be shut down. Otherwise, it can quickly create a dangerous learning environment.

Again, the instructor needs to keep the safety of the students in mind and evaluate all potential consequences.

Span of control is “the number of people one can effectively manage.” The more technical or hands on a training course is, the smaller the number of people a single instructor can safely control.

Span of control is “the number of people one can effectively manage.” The more technical or hands on a training course is, the smaller the number of people a single instructor can safely control.

In rope training, techniques (and teaching) may occur at multiple levels on a structure. For example, pick-off techniques or patient packaging in a simulated confined space rescue exercise. Certain techniques may require additional instructors at various levels to monitor students “going over an edge” and at the “pick-off” level. Or, with a confined space scenario, it may require an additional instructor to be physically located in the space to make sure patient packaging connections are correct prior to raising or life-loading the line.

Sometimes with in-house training, personnel can become complacent with double-checking all systems or having that extra set of eyes from an uninvolved participant. That’s why it is so important that every training exercise is carefully planned and followed through in all areas.

When training a group of your peers, it can often be difficult to prevent “freelancing” and to keep everyone on the same page. A well-planned training session will include a review of safety issues at the start – every time! The briefing should explain what will be covered (and allowed or not allowed) during the training. This will help students to understand that it’s more than just a “play” session, and will hopefully reduce the temptation for freelance activities.

It’s important for trainers and rescuers alike to watch this video. The training is being conducted in a live trench, which is definitely more realistic and more real world than setting trench panels between two containers. It is also more dangerous! The instructor ratio, training, and skills must be competent for the task. Acceptable conditions must be re-evaluated constantly and discussed between instructors. In some cases, like this one, a dangerous condition can be presented when students remove trench panels and equipment. This is the time to stop a class and halt all operations.

During this particular session, there was a large crack or separation in the dirt, which made the weight of the dirt unstable. As you will see, this caused the collapse of a large portion of the trench wall. In this particular situation, it was simply not worth trying to recover the trench panels at the cost of safety. The students were informed of the danger, how it was detected, and how it could be resolved.

Just remember… no piece of equipment or gear is worth injuring a student or instructor!

After everyone was informed of the danger of an impending collapse, the decision was made to let the wall collapse and to video it as a learning tool for that class and future classes. This video will give you a very clear picture of the speed and force that can occur in a trench collapse.

As you can see, the proper precautions were taken during this exercise in order to demonstrate the incredible power of a trench collapse.

An emergency plan was developed. A safety officer designated areas of safety as well as areas of dangers for students, instructors and observers. In order to maintain the stability of the opposing trench wall, a decision was made to keep a couple of other trench panels in place. A backhoe was used to slope sections of the trench and create a “safe zone” for the instructor to remove the struts, which in turn let the wall collapse. The force of the dirt was so powerful that it snapped a ¾-inch shore form panel and a 2" x 12" strongback like a toothpick.

What you won’t get from the video is the sense of force or vibration that was felt when the trench wall collapsed. It’s something the students will take away from the training along with a much greater respect for the power of a trench wall collapse.

Again, we stress that constant re-evaluation of conditions during technical rescue training is critically important for the safety of all involved. Instructors must have the ability to perceive any differences in the training environment or situation, be able to identify unacceptable conditions, and to take quick, corrective action. Students should also have the ability to stop a training evolution if they perceive danger or have concerns. It’s always best to stop and re-check everything!

Many times, it’s as simple as letting the students know if they see something that they think is dangerous or not quite right, or if they don’t quite understand, just yell, “STOP!”

Summary:

This video is a great learning tool that illustrates what can happen during “live trench” training. It dramatically demonstrates the speed and force of a trench wall collapse. However, it also affirms that with proper attention to the training environment and changing conditions, injury can be avoided.

It’s similar to personnel who have been exposed to swift water rescue in real world environments. They take away a much greater respect for the power of moving water, and it cannot be simulated in a swimming pool. Or, with high angle training, while it’s the same technique, rappelling from height versus a one-story building is a totally different experience.

As instructors, we must develop training that will give our students the experience and skills needed to perform their jobs safely. But we also need to keep them safe during training as well. Use this video and the story behind it to emphasize safety and proper planning during training sessions. It also helps us to realize that being a trainer or instructor comes with great responsibility. For me, it’s a constant battle between two thoughts: “No one should get injured during training,” versus “let no man’s ghost return to say his training let him down.”

The need to develop safety plans and perform risk analysis during training is an important part of our job as instructors, and student safety is our #1 priority.

Lanyard Safety

![]() Here's a question from one of our readers: How can you test a lanyard to determine if it is safe to use? Is there a standard checklist or procedure?

Here's a question from one of our readers: How can you test a lanyard to determine if it is safe to use? Is there a standard checklist or procedure?

Answer from the Roco Tech Panel: As with all safety and rescue gear, we recommend that you inspect, use and care for it in strict accordance with the manufacturer’s instructions. Of course, all equipment should be carefully inspected before and after each use. And, as we always say, “If there’s any doubt, throw it out!” Sometimes it’s less expensive to simply replace the gear versus going through any elaborate testing process. We did find the following information regarding lanyard inspections in an “OSHA Quick Takes” document. Thank you for your question!

Lanyard Inspection

To maintain their service life and high performance, all belts and harnesses should be inspected frequently. Visual inspection before each use should become routine, and also a routine inspection by a competent person. If any of the conditions listed below are found, the equipment should be replaced before being used.

To maintain their service life and high performance, all belts and harnesses should be inspected frequently. Visual inspection before each use should become routine, and also a routine inspection by a competent person. If any of the conditions listed below are found, the equipment should be replaced before being used.

When inspecting lanyards, begin at one end and work to the opposite end. Slowly rotate the lanyard so that the entire circumference is checked. Spliced ends require particular attention. Hardware should be examined under procedures detailed below.

HARDWARE

Snaps: Inspect closely for hook and eye distortion, cracks, corrosion, or pitted surfaces. The keeper or latch should seat into the nose without binding and should not be distorted or obstructed. The keeper spring should exert sufficient force to firmly close the keeper. Keeper rocks must provide the keeper from opening when the keeper closes.

Thimbles: The thimble (protective plastic sleeve) must be firmly seated in the eye of the splice, and the splice should have no loose or cut strands. The edges of the thimble should be free of sharp edges, distortion, or cracks.

LANYARDS

Steel Lanyard: While rotating a steel lanyard, watch for cuts, frayed areas, or unusual wear patterns on the wire. The use of steel lanyards for fall protection without a shock-absorbing device is not recommended.

Web Lanyard: While bending webbing over a piece of pipe, observe each side of the webbed lanyard. This will reveal any cuts or breaks. Due to the limited elasticity of the web lanyard, fall protection without the use of a shock absorber is not recommended.

Rope Lanyard: Rotation of the rope lanyard while inspecting from end to end will bring to light any fuzzy, worn, broken or cut fibers. Weakened areas from extreme loads will appear as a noticeable change in original diameter. The rope diameter should be uniform throughout, following a short break-in period. When a rope lanyard is used for fall protection, a shock-absorbing system should be included.

Shock-Absorbing Packs

The outer portion of the shock-absorbing pack should be examined for burn holes and tears. Stitching on areas where the pack is sewn to the D-ring, belt or lanyard should be examined for loose strands, rips and deterioration.

VISUAL INDICATIONS OF DAMAGE

Heat

In excessive heat, nylon becomes brittle and has a shriveled brownish appearance. Fibers will break when flexed and should not be used above 180 degrees Fahrenheit.

Chemical

Change in color usually appears as a brownish smear or smudge. Transverse cracks appear when belt is bent over tight. This causes a loss of elasticity in the belt.

Ultraviolet Rays

Do not store webbing and rope lanyards in direct sunlight, because ultraviolet rays can reduce the strength of some material.

Molten Metal or Flame

Webbing and rope strands may be fused together by molten metal or flame. Watch for hard, shiny spots or a hard and brittle feel. Webbing will not support combustion, nylon will.

Paint and Solvents

Paint will penetrate and dry, restricting movements of fibers. Drying agents and solvents in some paints will appear as chemical damage.

CLEANING FOR SAFETY AND FUNCTION

Basic care for fall protection safety equipment will prolong and endure the life of the equipment and contribute toward the performance of its vital safety function. Proper storage and maintenance after use is as important as cleaning the equipment of dirt, corrosives or contaminants. The storage area should be clean, dry and free of exposure to fumes or corrosive elements.

Nylon and Polyester

Wipe off all surface dirt with a sponge dampened in plain water. Squeeze the sponge dry. Dip the sponge in a mild solution of water and commercial soap or detergent. Work up a thick lather with a vigorous back and forth motion. Then wipe the belt dry with a clean cloth. Hang freely to dry but away from excessive heat.

Drying

Harness, belts and other equipment should be dried thoroughly without exposure to heat, steam or long periods of sunlight.

For the complete OSHA Quick Takes document, click here.

RescueTalk™ (RocoRescue.com) has been created as a free resource for sharing insightful information, news, views and commentary for our students and others who are interested in technical rope rescue. Therefore, we make no representations as to accuracy, completeness, or suitability of any information and are not liable for any errors, omissions, or delays in this information or any losses, injuries, or damages arising from its display or use. All information is provided on an as-is basis. Users and readers are 100% responsible for their own actions in every situation. Information presented on this website in no way replaces proper training!