Roco Rescue Releases Two New Fall Protection Programs for OSHA Compliant Workplaces

Roco Rescue Releases Two New Fall Protection Programs for OSHA Compliant Workplaces

Are you concerned about the potential for falls from height at your workplace?

Do you feel that your workers are not adequately trained in recognizing fall hazards, or do not have the proper training in the inspection and use of their fall protection equipment?

Does your fall protection program consider all the angles regarding work at height and fall protection?

Download our free Roco safety poster on the Hierarchy of Fall Protection.

New Roco Fall Pro Course: Competent Person for Fall Protection

Roco Rescue is proud to announce the addition of a comprehensive Competent Person for Fall Protection course as an addition to our already extensive catalog of Technical Rescue, Compliance, and Safety courses.

The two day (16 hour) Competent Person course focuses on OSHA and ANSI requirements and guidance to provide the Competent Person the knowledge and skills that will enable them to provide their employer a solid foundation for establishing or improving their comprehensive fall protection program

This course emphasizes legislated as well as consensus standard fall protection requirements and guidance for various industries as well as exposing the attendees to a variety of modern fall protection equipment solutions and techniques. The hierarchy of fall protection is used as the building block for the most protective approach for abating fall hazards in the workplace. The attendee will have a solid understanding of how to evaluate fall hazards in the workplace by completing a field exercise using a “Fall Hazard Survey Report Template” that identifies fall hazards and uses the hierarchy of fall protection to provide the most protective and feasible solution to address the identified hazards.

Exposure to modern fall protection equipment and emerging technologies -especially the availability of pre-engineered fall protection solutions- arms the student with an extensive toolkit for addressing existing fall hazards in their workplace. Equipment and equipment systems such as body support, connectors, modern lanyards, self-retracting lanyards, horizontal and vertical lifelines, anchor connectors, as well as other specialty equipment will be covered and examples will be available to employ during the class.

The often overlooked need to understand and provide a rescue capability for fallen/suspended workers and workers isolated at height will be covered. The use of the “Roco Suspended Worker Rescue Pre-plan” will be covered in a live field exercise. Included will be a demonstration and practice rescues utilizing a pre-engineered rescue system that may provide the “prompt rescue capability” of fallen workers for most situations as required by both OSHA and ANSI.

New Roco Fall Pro Course: Competent Person - Train the Trainer:

New Roco Fall Pro Course: Competent Person - Train the Trainer:

Upon completion of Roco’s Competent Person for Fall Protection Course we offer the option to stay on for our Competent Person Trainer course. This course includes an additional two days (16 hours) that prepares the Competent Person to train their own employees to the level of Authorized and Competent Persons. The course opens with a thorough lecture/discussion on the adult learner.

Tried and proven steps that are invaluable in providing a systematic workforce education program specific to Competent and Authorized Persons for fall protection are covered. Areas such as gap analysis, instructional triads, three part learning objectives, measurements, dealing with the adult learner and their varied backgrounds are just some of the preparatory lessons. This is followed by a thorough section on preparing and utilizing lesson plans which are then put into practice as the attendees prepare for and deliver actual lessons to their fellow students on the various teaching modules.

The Competent Person for Fall Protection and the Competent Person Trainer Courses are available as private training at Roco Training Center in Baton Rouge, Louisiana or Roco can deliver the course at your facility as a private class. Please call (800) 647-7626 for more details or to schedule.

New Roco Fall Pro Course: Competent Person - Train the Trainer:

New Roco Fall Pro Course: Competent Person - Train the Trainer:

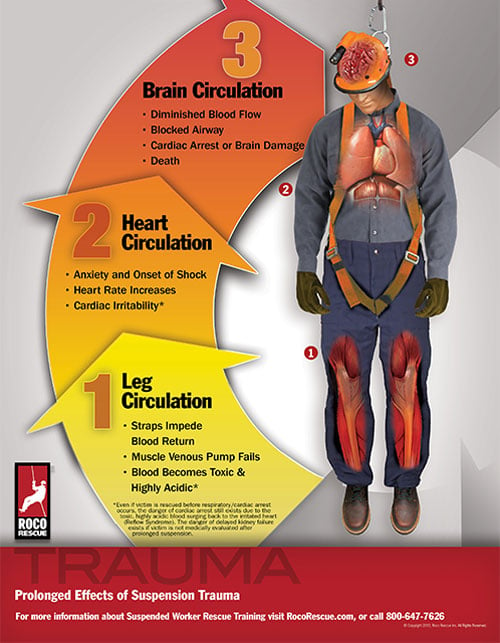

2. Heart Circulation: As the body goes into distributive shock, the heart must increase the rate and strength of its contractions to compensate. To compound this, the suspended worker may be experiencing a high degree of fear and anxiety, which releases adrenalin into the bloodstream which also causes the heart to work harder and faster. This places increased demands on the heart, which is receiving less blood flow and thus less oxygen. The heart becomes irritable and is prone to localized tissue damage, dysrhythmias or both. This is especially a concern once the worker is rescued and the toxic blood is allowed to surge from the legs to the irritable heart. This is known as reflow syndrome and has caused several victims to go into sudden cardiac arrest upon rescue.

2. Heart Circulation: As the body goes into distributive shock, the heart must increase the rate and strength of its contractions to compensate. To compound this, the suspended worker may be experiencing a high degree of fear and anxiety, which releases adrenalin into the bloodstream which also causes the heart to work harder and faster. This places increased demands on the heart, which is receiving less blood flow and thus less oxygen. The heart becomes irritable and is prone to localized tissue damage, dysrhythmias or both. This is especially a concern once the worker is rescued and the toxic blood is allowed to surge from the legs to the irritable heart. This is known as reflow syndrome and has caused several victims to go into sudden cardiac arrest upon rescue. To maintain their service life and high performance, all belts and harnesses should be inspected frequently. Visual inspection before each use should become routine, and also a routine inspection by a competent person. If any of the conditions listed below are found, the equipment should be replaced before being used.

To maintain their service life and high performance, all belts and harnesses should be inspected frequently. Visual inspection before each use should become routine, and also a routine inspection by a competent person. If any of the conditions listed below are found, the equipment should be replaced before being used. By Roco Chief Instructor Pat Furr

By Roco Chief Instructor Pat Furr “It is our experience that the victims, would-be rescuers, and co-workers either fail to adhere to their emergency plans or simply do not have a plan in place, with catastrophic results... In the last year alone, we have responded to three confined space rescues.”- Battalion Chief Jack Wise of the Los Angeles Fire Department

“It is our experience that the victims, would-be rescuers, and co-workers either fail to adhere to their emergency plans or simply do not have a plan in place, with catastrophic results... In the last year alone, we have responded to three confined space rescues.”- Battalion Chief Jack Wise of the Los Angeles Fire Department