As anyone who has ever been summoned to an industrial site for a confined space rescue, or has taken the opportunity to practice rescue drills in these facilities knows, sometimes the working area for the rescue team can be a tad cozy. By “cozy” we mean cramped. If there is the need for a haul of the rescuers or victim after a lower, these cramped conditions can cause multiple problems. Consider it a challenge to overcome, and use your rope rescue know-how to come up with an efficient solution that will not only reduce congestion at the working area, but will most likely provide for a much faster haul of the rescue package.

As anyone who has ever been summoned to an industrial site for a confined space rescue, or has taken the opportunity to practice rescue drills in these facilities knows, sometimes the working area for the rescue team can be a tad cozy. By “cozy” we mean cramped. If there is the need for a haul of the rescuers or victim after a lower, these cramped conditions can cause multiple problems. Consider it a challenge to overcome, and use your rope rescue know-how to come up with an efficient solution that will not only reduce congestion at the working area, but will most likely provide for a much faster haul of the rescue package.

First of all, if the space lends itself to a vertically mounted block and tackle, the problem is greatly reduced. However, if there is no overhead anchor available and the use of a portable overhead anchor such as a tripod is not feasible then a “lane” for the haul team may be necessary. At times, even the use of a vertically mounted block and tackle may require a solution to a congested working area.

Sometimes we are confronted with a very short throw between the mechanical advantage anchor point and the edge of the portal. This may cause multiple resets of the haul system, be it a piggyback system or a Z-Rig. These short throws with multiple resets will really slow down the progress of hauling the rescue package and can become a significant hazard when the need for rapid retrieval is needed. If the opportunity presents itself, take advantage of a simple change of direction on the haul system. At times, a single 90-degree change of direction can convert a short 3-4 foot throw into a throw many times longer. We see this all the time on catwalks, yet it is often overlooked by our rescue teams when we throw scenario-based training evolutions at them. Yes, it does require some extra equipment which typically amounts to a single sheave pulley, a carabiner, and a utility strap. It also adds some frictional losses at that directional pulley, but the advantage gained by extending the throw from 3-4 feet to 20 or more feet, far outweighs the disadvantages of extra equipment, added friction, and time needed to make the change.

If the opportunity presents itself, take advantage of a simple change of direction on the haul system. At times, a single 90-degree change of direction can convert a short 3-4 foot throw into a throw many times longer. We see this all the time on catwalks, yet it is often overlooked by our rescue teams when we throw scenario-based training evolutions at them. Yes, it does require some extra equipment which typically amounts to a single sheave pulley, a carabiner, and a utility strap. It also adds some frictional losses at that directional pulley, but the advantage gained by extending the throw from 3-4 feet to 20 or more feet, far outweighs the disadvantages of extra equipment, added friction, and time needed to make the change.

If a single change of direction doesn’t quite solve the short throw problem, consider two, or even more changes of direction in order to position the haul team in an area thatthey can “walk the haul” using their leg strength instead of being bunched up and using their arm strength only. Of course, it gets to a point where too many changes of direction exhausts the equipment cache or creates so much friction that any advantage is lost.

As in any rescue situation, a good cohesive team is a great benefit. If the situation causes the team to be bunched up on top of each other, remember to scan the area for an opportunity to open things up a bit. Sometimes that change of direction does wonders for the ability of the team to take full advantage of their strength in numbers, and creates a situation where if needed, speed can be a lifesaver.

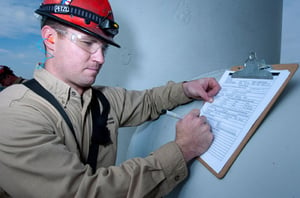

The author, Pat Furr, reporting for duty...

If you’re the one who’s responsible for setting up proficiency training for your team, ask your team members to come up with some ideas that are different from your typical drill. You might be surprised with what they come up with. If you’re a team member, approach your training manager with some suggestions to change things up a bit. Once the idea is planted and your team starts to run a variety of training scenarios, the idea will catch on. In fact, team members may try to “outdo” each other on coming up with the next new scenario.

If you’re the one who’s responsible for setting up proficiency training for your team, ask your team members to come up with some ideas that are different from your typical drill. You might be surprised with what they come up with. If you’re a team member, approach your training manager with some suggestions to change things up a bit. Once the idea is planted and your team starts to run a variety of training scenarios, the idea will catch on. In fact, team members may try to “outdo” each other on coming up with the next new scenario.