It’s December 21st on a Saturday night, and the plant is running on a skeleton crew. Operations wants to get a head start on annual preventive maintenance and decides to knock out several permit required confined space entries before the majority of the work is to be done after the New Year.

Randy has just finished the third of five vessels that are identical in configuration. He and his authorized attendant and good friend, Hector, have been working together for over 15 years and they both know the drill. They have changed out the stainless-steel bolt sets on the agitator blades of these vessels every year at about this same time. The entry supervisor has just closed out the permit for the third vessel. After reviewing the permit for the fourth vessel and helping with the pre-entry atmospheric monitoring, he signs the permit authorizing entry.

Randy has just finished the third of five vessels that are identical in configuration. He and his authorized attendant and good friend, Hector, have been working together for over 15 years and they both know the drill. They have changed out the stainless-steel bolt sets on the agitator blades of these vessels every year at about this same time. The entry supervisor has just closed out the permit for the third vessel. After reviewing the permit for the fourth vessel and helping with the pre-entry atmospheric monitoring, he signs the permit authorizing entry.

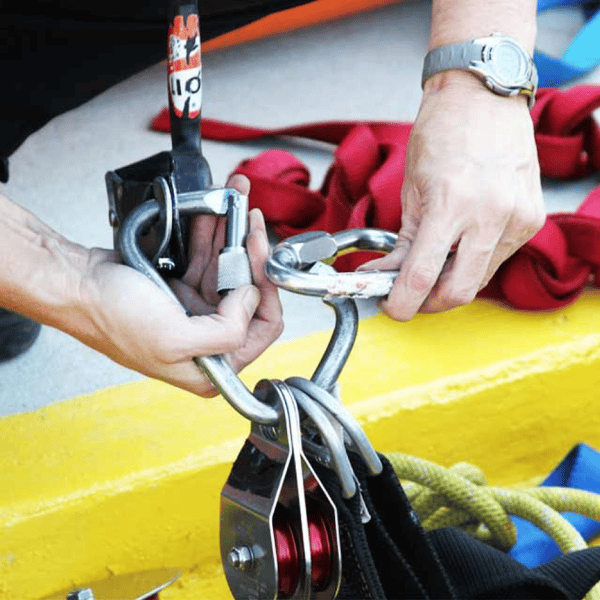

Hector checks Randy’s harness and the attachment of the non-entry rescue retrieval cable to his dorsal D-ring, and double checks the davit arm and the mounting point of the self-retracting lifeline with the built-in retrieval winch. As Randy climbs 25 feet down the rope ladder to access the bottom of the vessel, all is going according to plan. As he steps off the ladder and begins to loosen the first bolt set, he slips on the concave floor of the stainless-steel vessel. Before he can react, he strikes his head on the agitator blade which causes a 5-inch gash to his left temple and knocks him unconscious. He falls between two of the agitator blades and then slides to the bottom of the vessel with his retrieval line wrapped over one of the blades and under another. Hector tries to winch his friend out of the space only to find that Randy’s limp body gets wedged under the agitator blade. You can probably guess what happened next.

Keep additional personnel (even rescuers) out of the space

unless absolutely necessary.

Realizing there is no entry rescue capability on this shift, Hector’s gut reaction is to enter the space to help his friend. In his rush, he slips from the rope ladder and falls 20 feet to his death. When the entry supervisor arrives 30 minutes later to close the permit and initiate the last entry, he sees two bodies at the bottom of the space.

Understand OSHA Rescue Requirements

Are there permit required confined spaces at your worksite? Are employees allowed to enter these spaces? If you answered yes to these two questions, it is critically important to understand the OSHA requirements for rescue. As part of a written permit space program, the employer must “Develop and implement procedures for summoning rescue and emergency services, for rescuing entrants from permit spaces, for providing necessary emergency services to rescued employees, and for preventing unauthorized personnel from attempting a rescue.”

When considering what methods should be used for rescuing authorized entrants, the safety of the rescuer(s) should be considered as important as the effectiveness of the rescue technique. If it is possible to perform non-entry rescue of the entrant(s), that should always be the first choice. It’s always a given – keep additional personnel (even rescuers) out of the space unless absolutely necessary. It is important to consider potential scenarios that could arise when determining if non-entry (or retrieval) rescue is sufficient.

Non-Entry Rescue

What are the requirements for non-entry rescue? OSHA states, “To facilitate non-entry rescue, retrieval systems or methods shall be used whenever an authorized entrant enters a permit space, unless the retrieval equipment would increase the overall risk of entry or would not contribute to the rescue of the entrant.”

An assessment should carefully consider both capabilities and limitations of the retrieval system for any planned or unplanned condition that may arise during entry.

Let’s examine this further. What conditions would preclude the use of non-entry retrieval systems? Here are some guidelines that OSHA will use to make this determination:

- A permit space with obstructions or turns that prevent pull on the retrieval line from being transmitted to the entrant does not require the use of a retrieval system.

- A permit space from which an employee being rescued with the retrieval system would be injured because of forceful contact with projections in the space does not require the use of a retrieval system.

- A permit space that was entered by an entrant using an air supplied respirator does not require the use of a retrieval system if the retrieval line could not be controlled so as to prevent entanglement hazards with the air line.

Assess The Space

The ONLY way to determine if a non-entry retrieval system will provide adequate safety for entrants and satisfy OSHA’s requirement is to perform an honest and thorough assessment. This assessment should provide careful consideration for the capabilities and limitations of the retrieval system for any planned or unplanned condition that may arise during entry. We have all heard of “Murphy’s Law” and most of us have experienced the effects of that particular law. I encourage you to remember that Murphy is always lurking close by.

So, when evaluating these spaces to determine if non-entry or entry rescue is the appropriate choice, always ask yourself “what if?” For the fictitious accident that opened this article, the plan was to do all the work on the near side of the agitator blade directly below the top portal. In that case, it would have been safe to assume non-entry retrieval was the only plan needed for rescue. Enter Murphy… Was the rescue plan developed with the assumption that the planned work activities would always ensure the successful use of the retrieval system, but failed to consider the “what ifs”? Some might say that we can “what if” things to death. Let’s turn that around; we SHOULD “what if” these questions in an effort to PREVENT death.

If there is any reasonable potential for an unplanned change

in the conditions, then an entry rescue capability

must be in place as a backup.

When evaluating permit spaces to determine the appropriate rescue capability, please explore those “what ifs.” This is not to say that in the case cited above that the only option would have been entry rescue. That may not be necessary and if the non-entry retrieval system would have worked, then there is no need to expose rescuers to the hazards of entering the permit space. But there was a potential for the condition to change, and it sure did. So, recognizing that potential, an entry rescue capability should have been planned in the event that the change in conditions rendered the non-entry rescue system ineffective.

Backup Plan

The point of this article is to consider non-entry rescue as the default for assisted permit space rescue unless the conditions cited by OSHA are present. At that point, entry rescue must be planned. But this isn’t necessarily a one or the other choice. As we can see from this story, it is sometimes best to plan for non-entry rescue as the primary technique, but if there is any reasonable potential for an unplanned change in conditions, then an entry rescue capability must be in place as a backup.

This article was originally featured on the cover of the March 2014 issue of ISHN, and authored by retired Roco Chief Instructor Pat Furr.

Additional Resources

- Non-Entry Confined Space Rescue…Are You Sure?

- Confined Space Types - Are All Your Bases Covered?

- Confined Space Rescue Types Chart & Compliance Guide (pictured here)

The short answer…. of course, it is! Whether you are a large company or a small company (like ours), we have experienced that VPP can be a “win-win-win” for all who participate. The collaboration between employers, employees, and OSHA is one of the most refreshing aspects of VPP participation.

The short answer…. of course, it is! Whether you are a large company or a small company (like ours), we have experienced that VPP can be a “win-win-win” for all who participate. The collaboration between employers, employees, and OSHA is one of the most refreshing aspects of VPP participation.

That is largely due to the folks that I have been surrounded with in that time. They nudged me, and at times that nudge was pretty solid, in the right direction. Because of the nature of rescuers in general, some of your best human qualities were bound to rub off on me. And for that, I thank you.

That is largely due to the folks that I have been surrounded with in that time. They nudged me, and at times that nudge was pretty solid, in the right direction. Because of the nature of rescuers in general, some of your best human qualities were bound to rub off on me. And for that, I thank you.