Fall Protection Planning - Lives are on the Line

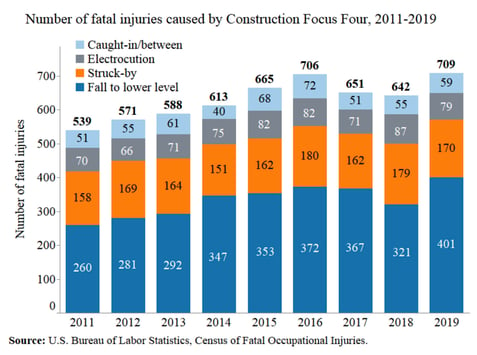

We’ve all heard it before, “falls are one of the leading causes of death in the industry.” In fact, falls have been the leading cause of death in the construction industry, year after year, for over a decade now. Additionally, Fall Protection (29 CFR 1926.501) and other related standards continue to land on OSHA’s “Top 10 Most Frequently Cited Standards” list each year.

According to NIOSH, 401 of the 1,102 construction fatalities recorded in 2019 were due to falls. To raise awareness of this hazard, OSHA now conducts a “National Fall Protection Safety Stand-down” to prevent falls in construction and has done so each year since 2014. The 2022 Stand-Down is May 2-6, but OSHA encourages holding your own stand-down any time, year-round.

With all of the emphasis on fatal falls, why are workers continuing to fall to their deaths? More importantly, what can we do to prevent them? Well, I’m glad you asked!

There are many actions that employers can take to prevent fatal falls from occurring in the industry; however, the adage “an ounce of prevention is worth a pound of cure” definitely comes to mind here. The most effective measure that any company can take to prevent fatal falls is to implement proper planning before work begins. An effective fall protection plan is multi-faceted and contains multiple steps, all of which should be given great attention to detail.

What should a fall protection plan include?

1) General Information About the Jobsite

As with any plan, an effective fall protection plan should begin with general information about the task at hand. What type of jobsite or facility is this? Is the job taking place at a residential home, a new construction project, or an industrial manufacturing facility? What type of work is being done? Consider electrical work, roofing, hot work, confined space work, or other tasks that may be a contributing factor in falls. Are there any existing fall protection measures in place? In many cases, permanent ladders and guardrails are in place throughout the jobsite; however, on new construction, there may not be any existing fall protection measures. Are there any work surfaces that could affect the job? Take note of areas that may be slippery, areas that could be abrasive, uneven or unlevel areas or areas with trip hazards. Will the weather impact the safety of the job? Consider how rain, wind, or ice accumulation could impact the jobsite. What is the estimated duration of the job? Long-term jobs may require different solutions from short-term jobs. In some instances, scaffold erection may not be an effective use of time and mobile aerial lifts may be more feasible.

2) Assessment of All Fall Hazards on Site

Once the general information of the jobsite has been documented, a thorough assessment of all fall hazards on the jobsite should be conducted and documented. OSHA has different fall protection requirements for General Industry and Construction. While there are a nearly unlimited number of ways that fall hazards can present on a jobsite, the following are a few examples of the more common situations to look for:

- Open-sided walking/working surfaces

- Open-sided ramps, runways, and platforms

- Floor openings

- Wall openings

- Elevator Shafts

- Stairwells

- Trenches

Do not skimp out on this step of your plan. After all, if you do not identify a fall hazard, you will not be able to protect against it! Consider including workers of all levels in the hazard assessment; every worker has a different perspective and may identify things that are missed by others.

3) Outline of Fall Protection Measures to be Used

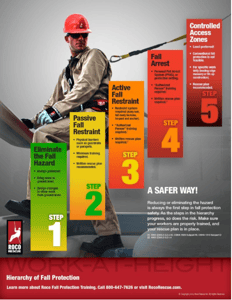

Now it’s time to decide how you are going to protect workers from the hazards identified. The hierarch of fall protection is a 5-tiered approach, and the preferred method to eliminate or reduce the risk of falls. The 5 tiers are as follows:

-

Hazard Elimination (best practice)

The most effective measure of protecting workers from a fall hazard is to eliminate it all together. If possible, relocate the work to ground level or eliminate the exposed edge or opening. - Passive Fall Protection

In many cases, elimination of the hazard is not possible or feasible. The next best measure to implement is to provide passive fall protection which includes things like guardrails or hole covers. Passive fall protection provides a lower possibility of error as it does not rely on the use of personal protective equipment (PPE). - Active Fall Restraint

In some cases, passive fall protection is not warranted as the duration of exposure may not offset the cost of implementing passive protection or the task being performed may not allow for passive fall protection. Active fall restraint is a type of PPE that limits a worker’s range of movement so that they cannot physically travel to the area of the fall hazard. This method is preferred over fall arrest as it significantly reduces the likelihood of secondary injury due to falls and the need to perform a suspended worker rescue. However, there are many cases where a worker must enter the area of the hazard to perform work. - Active Fall Arrest

An important note with active fall arrest systems is that they do not prevent a worker from falling but rather prevent the worker from contacting lower levels after the fall has occurred. One important, and often overlooked, element of this is having an effective rescue plan. Be sure to have a plan in place in the event that someone does fall. You must also ensure that workers are trained and understand how to properly use their equipment as well as its limitations. More on that later. - Establishing Controlled Access Zones (least effective)

As a last resort, controlled access zones may be established to limit essential personnel into the area of the fall hazard. These methods generally include safety monitoring systems, warning lines or horns, or control lines. It is important to note that these controls are the least effective as they do not provide any physical means of protection. It is strongly recommended that all efforts have been exhausted to use the previous methods in the hierarchy before settling on controlled access zones.

4) Outline of Use, Maintenance, and Inspection Procedures for Equipment Being Used

Now that the methods of fall protection and prevention for the jobsite have been established, an outline of use, maintenance, and inspection procedures for the equipment used should be documented. Be sure to include proper assembly and disassembly procedures for equipment according to the manufacturer's recommendations. Ensure that a process exists for a competent person to inspect equipment at least annually or as required by manufacturer’s recommendations as well as a process for inspection of safety equipment by the end-user before each use. Any defective equipment must be tagged and removed from service immediately.

5) Outline of the Handling, Storage, and Securing of Tools and Materials on the Jobsite

This section of the fall protection plan goes hand-in-hand with the previous section. Establish a clear outline of how the equipment will be handled and stored on the jobsite. If equipment is not stored properly, it may become contaminated or damaged and render unsafe for use. Storage and handling of equipment vary from jobsite to jobsite but remember to protect equipment against heat, moisture, and chemicals when storing your equipment.

6) Outline of Overhead Protection to be Used

While not directly related to preventing workers themselves from fall hazards, it is important to address how workers in the area of overhead work will be protected. The use of toeboards, debris nets, or other side guards can be effective in preventing tools and material from falling below. Lanyards used to tether tools to the worker are also a great way to avoid dropped objects. Ensure that workers are notified of overhead work in the area with signs and barricades when possible. Consider postponing overhead work in unfavorable weather conditions and secure loose objects whenever possible.

7) Detailed Rescue Plan

Perhaps the most often overlooked item of a fall protection plan is the rescue plan. Many workers in the construction industry know that they must tie-off when working at heights; however, few take the time to think about what happens if/when they fall. Take the time to discuss and document the plan of action to be taken when someone falls. Suspension trauma is a life-threatening condition that can develop when a worker is hanging from their fall arrest system and can be lethal in as little as five minutes. Consider the use of a specialized rescue team for complex scenarios or be sure that you have the proper equipment, training, and proficiency to perform the rescue if needed. Remember, with fall protection – your life is literally on the line!

8) Employee Training and Instructions

Without adequate training, even the most effective plan is worthless. Remember that jobsites are dynamic and that fall hazards that were not present yesterday may be present today. For this reason, ensure that workers are trained to identify fall hazards and how to take measures to reduce or eliminate the hazard. Be sure that workers know when, where, how, and what fall protection equipment is to be used for the task or hazard in question. Also, ensure that workers know how to properly inspect their equipment before use and what to do with equipment that does not pass inspection. Most importantly, ensure that workers are trained on the fall protection plan, have easy access to it, and know how to access it for reference at any time.

Summary

Despite the increased emphasis placed on falls, they continue to be the number one killer in the construction industry. Unfortunately, the one thing that doesn’t seem to fall is the number of fatalities resulting from it. While there are many actions that employers can take to reduce the likelihood of a fall occurring, the most effective measure is to have an adequate fall protection plan in place. Establish the details of the job, identify the fall hazards, and develop a method to eliminate or reduce the risk associated with the hazard. Establish a guide for proper use, maintenance, inspection, and storage of fall protection equipment and ensure that workers have the training they need to do the job safely. Last but not least, ensure that you have an adequate rescue plan in the event that a fall does occur. Remember, with fall protection – your life is on the line!

Chris McGlynn is the Director of Safety/VPP Coordinator for Roco Rescue. He is a Certified Safety Professional (CSP) through the Board of Certified Safety Professionals as well as a Certified Confined Space and Rope Rescue Technician, and a Nationally Registered Paramedic. As Director of Safety, Chris oversees all corporate safety initiatives, ensuring that employees at Roco have the tools and training that they need to do their work safely and effectively. He is also responsible for managing Roco's Safety Services Division, which provides trained safety professionals for turnarounds and other special projects. Finally, Chris serves as the VPP Coordinator for Roco, continuing Roco’s long-standing commitment to excellence in safety and health. Roco has been an OSHA VPP Star Worksite since 2013.

McGlynn is the Director of Safety/VPP Coordinator for Roco Rescue. He is a Certified Safety Professional (CSP) through the Board of Certified Safety Professionals as well as a Certified Confined Space and Rope Rescue Technician, and a Nationally Registered Paramedic. As Director of Safety, Chris oversees all corporate safety initiatives, ensuring that employees at Roco have the tools and training that they need to do their work safely and effectively. He is also responsible for managing Roco's Safety Services Division, which provides trained safety professionals for turnarounds and other special projects. Finally, Chris serves as the VPP Coordinator for Roco, continuing Roco’s long-standing commitment to excellence in safety and health. Roco has been an OSHA VPP Star Worksite since 2013.

Additional Resources

- Fall Hazard Survey (pictured here)

- Hierarchy of Fall Protection Poster

- Personal Fall Arrest Systems (PFAS)